- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

American B-H. O. & S. M. Co.

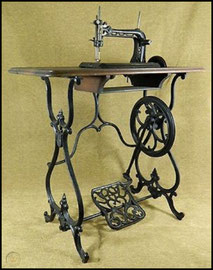

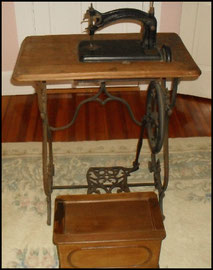

EARLY MACHINES

AMERICAN

COMBINATION OR PLAIN FAMILY MACHINE

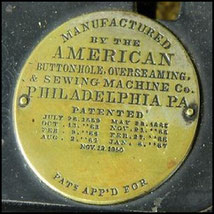

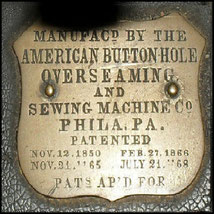

These early machines have the round brass medallion (Trade-Mark) with the name of the company and related patent dates; the later machines have the serial number on these medallions or Trade-Marks, the machine on the stand shown below does not have a serial number on the medallion, nor elsewhere on the machine; perhaps it was placed as in the machine shown in the right side picture. (see video 1)

This machine is really two machines combined in one, making both the Shuttle or Lock-Stitch and the Over-seaming and Button-hole stitch with equal facility and perfection. It will execute in the very best manner: Stitching, Braiding, Hemming, Felling, Cording, Tucking, Gathering, Sewing-on and Binding (Straight or Scollop) and in addition make beautiful Button Holes and Eyelet Holes in Cloth, Leather or Lasting, besides Over-seaming and Embroidering the edge of Garments. We especially invite the attention of Manufacturers of Shoes to its well executed work on Lasting and Leather and of Tailors to its capacity for so many varieties of their work. We also invite the attention of manufacturers to our samples of embroidering the edge of Blankets and Knit Goods with Zephyr Wool and we Challenge competition to produce such beautiful results. We also particularly invite attention to our Plain Family Machines, the lightest, the simplest, the most durable and easy running of any Shuttle Machines in the world. The Shuttle is self-threading, thus saving all perplexity with the under thread and the whole construction of the Machine is simple, elegant and convenient.

Head of a treadle, button-hole sewing machine, no. 1.342, by the American Button-Hole, Overseaming and Sewing Machine Co., Philadelphia, United States, 1868. There is a needle and swinging hook both above and below the table. This means that the machine is two chain-stitch machines combined, enabling it to sew around a button-hole.

collection.sciencemuseumgroup.org.uk

NEW AMERICAN No.1

The New American machine was introduced in 1873

The New American machine was introduced in 1873 as two models the No. 1 Light Family Machine and the No. 2 Manufacturing Machine for family, tailoring and leather work. Both models were available with various forms of cabinet work ranging from the Plain Table to the top of the range Full Cabinet in Black Walnut with Curled Walnut or Rosewood panels.

It would seem early "American No. 1" machines come out with a new Trade-Mark shape. It still have the name of the company and related patent dates but does not have a serial number on it yet.

NEW AMERICAN No.2

The New American machine was introduced in 1873 as two models the No. 1 Light Family Machine and the No. 2 Manufacturing Machine for family, tailoring and leather work. Both models were available with various forms of cabinet work ranging from the Plain Table to the top of the range Full Cabinet in Black Walnut with Curled Walnut or Rosewood panels.

IMPROVED AMERICAN No. 1

AMERICAN No.3 BUTTON-HOLE

NEW AMERICAN No.5

NEW AMERICAN No. 6

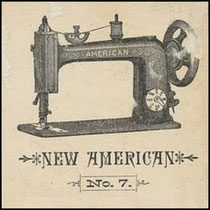

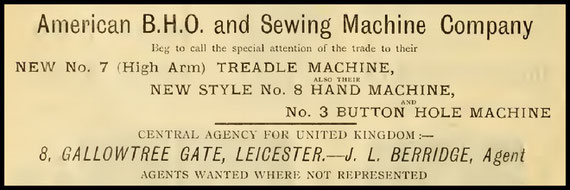

THE "AMERICAN" No. 7 MACHINE

High Arm

The American No. 7 was introduced in 1881

The improved American No. 7 was introduced in 1883

In presenting the New American Sewing Machine to the world the world the American Company have to the people a very handsome, artistic and scientific machine, the result of many years of observant experience, abundant facilities for manufacture and a thorough knowledge of what the people need. It is adapted to a very wide range of work, lightly but very durably made, handsomely ornamented and with a number of features of improvement that must infallibly make it a popular and readily selling machine. It has great capacity under the arm and is strikingly simple in its mechanical parts. One of its points of merit is an ingenious arrangement to regulate the length of the stitch so as to change while operating and return to the original number of stitches per inch; the advantage of this arrangement will be readily appreciated by sewing machine people. It has a very even, self-adjusting and graduated tension. It is entirely self-threading at all points. Its perfect, almost self adjusting and graduated tension is under easy control of the operator and always positive in its working. It is entirely self-threading at all points including the shuttle. The needle is self-setting and requires no mark or screw-driver and the attachments are quickly and easily placed and fastened. The shuttle has an easy oscillating motion, causing it to keep its proper place against the race. The shuttle which is made of cast-steel and hardened in all its parts, is perfectly self-threading. The bobbin holds a large amount of thread and by means of the loose balance wheel can be wound without running the machine. The shuttle lever and feed lever are nicely balanced, both working on a central pivot. The press-bar has a long, hardened steel guide giving perfect steadiness to the presser-foot. The pressure can very readily be adjusted to suit different fabrics. The feed is strong and positive in its motion; requiring no spring, it has a double motion and is novel in its construction. The stitch-regulating arrangement is unique and like the feed is pecular to the American machine. The dial plate always indicates the number of stitches in an inch space; the crank and plunger may be set on and the stitch can be regulated while the machine is in motion. The height of feed can be regulated at pleasure by means of an eccentric.

Sewing Machine Gazette (February 1882)

AMERICAN No. 8

Hand Machine

This Machine is particularly adapted to ladies who cannot work a treadle machine. It is constructed that the different attachments can be used with it and it can be operated with greater speed than any other hand machine ever offered the public. It is also a very convenient machine for families going to the country or sea shore for a season, as it can be packed in a trunk and taken from place with ease. We have two styles, one with Iron Stand and one with Walnut Case.

AMERICAN No. 9

American No. 9 used a conventional vibrating shuttle.

US PATENTS ON TRADEMARK 1

US 7.776 Allen B. Wilson November 12, 1850

US 24.863 E. A. Goodes & E. L. Miller July 26, 1859

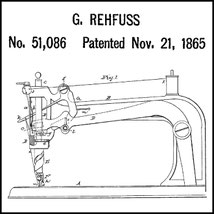

US 40.311 George Rehfuss October 13, 1863

USRE 1.616 E. A. Goodes & E. L. Miller February 9, 1864

US 43.742 George Rehfuss August 2, 1864

US 47.905 George Rehfuss May 23, 1865

US 51.086 George Rehfuss November 21, 1865

US 52.932 George Rehfuss February 27, 1866

................ George Rehfuss January 8, 1867 (*)

(*) for this date we have 3 patents. The two first are assigned to American Button-Hole, Cording, Braiding and Machine Company; the last patent to the American Button-Hole Sewing Machine Company.

US PATENTS ON TRADEMARK 2

US 7.776 Allen B. Wilson November 12, 1850

US 51.086 George Rehfuss November 21, 1865

US 52.932 George Rehfuss February 27, 1866

US 73.119 George Rehfuss January 7, 1868

US PATENTS ON TRADEMARK 3

US 7.776 Allen B. Wilson November 12, 1850

US 40.311 George Rehfuss October 13, 1863

USRE 1.616 E. A. Goodes & E. L. Miller February 9, 1864

US 43.742 George Rehfuss August 2, 1864

US 47.905 George Rehfuss May 23, 1865

US 51.086 George Rehfuss November 21, 1865

US 52.932 George Rehfuss February 27, 1866

................. George Rehfuss January 8, 1867 (*)

US 73.119 George Rehfuss January 7, 1868

US 80.090 George Rehfuss July 21, 1868

US 91.484 George Rehfuss June 15, 1869

US 102.710 George Rehfuss May 3, 1870

US 114.197 George Rehfuss April 25, 1871

US 121.896 George Rehfuss December 12, 1871

US 133.487 George Rehfuss November 26, 1872

US D 6.375 George Rehfuss January 28, 1873

US RE 5.260 George Rehfuss January 28, 1873

US 137.028 George Rehfuss March 18, 1873

US 139.421 George Rehfuss May 27, 1873

(*) for this date we have 3 patents. The two first are assigned to American Button-Hole, Cording, Braiding and Machine Company; the last patent to the American Button-Hole Sewing Machine Company.