- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

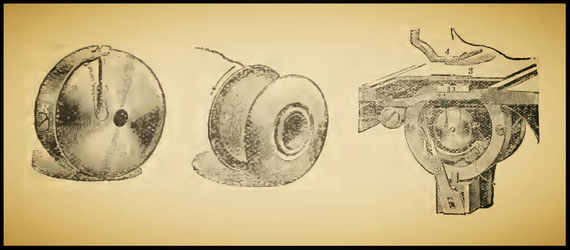

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

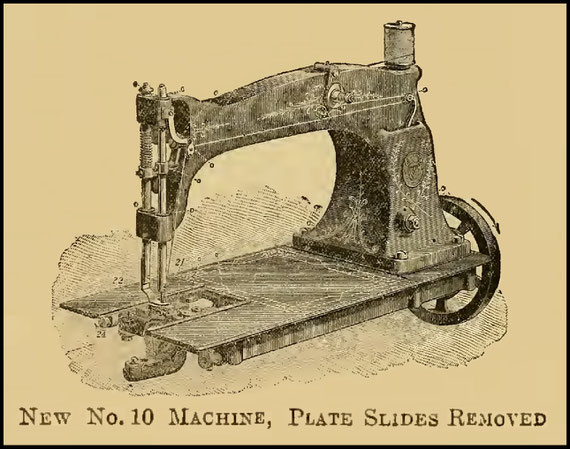

WHEELER & WILSON No. 10

For Boot and Shoe Manufacturing

From 1882 To 1899 c.

The new W&W No.10 machine is especially designed for heavy work, Tailoring, Upholstery, Stay and Corset Manufacture, as well as for Stitching Leather. The Company have in their New No.10 a machine, which possesses several valuable improvements. It is a machine specially adapted for heavy work, but, notwithstanding its larger size, it is so constructed as to run at as high a rate of speed as the lightest lock-stitch machine, without irregularity of tension. There is less friction in the feed motion and an improved mode of altering the stitch. There is, besides, greater space for work under the arm and more direct action to the needle from the driving power. The under spool being held by a spring, partly on the ring and partly on the hook, ensures a more regular tension. The clear space under the arm, without any projections, prevents any obstruction to the work, also without variation of tension. The take-up being more continuous and regular, prevents jerking.

The Company's new No. 8 Machines are quite as extensively purchased in lots from 60 upwards at a time and lately saw an order for 100 of them from a well known firm. The new No.6 machine (the one recommended for leather work) is likewise in great demand and as it may be of interest to the trade we append the Judges report upon the Company's New No. 6 machine at the late American Institute Fair, where the Wheeler & Wilson Company received the highest award.

The Sewing Machine Gazette 1882

read the full article

*********************************************************

US PATENTS FOR W&W No.10

*********************************************************

US 303.453 Freeland W. Ostrom

Button hole for W&W No. 10

This invention is an improvement on that described in application No. 63.023, filed June 1, 1882 and has for its object to simplify the construction and operation of the same.

...Figure 1 is a plan or top view of a Wheeler & Wilson No. 10 machine with my improvements added...

Assignor to the Wheeler & Wilson Manufacturing Company

August 12, 1884

*********************************************************

US 317.749 George H. Dimond

Thread Clamp for W&W No. 10

Specification forming part of Letters Patent US 317.749, May 12, 1885

Application filed December 14, 1883

Assignor to the Wheeler & Wilson Manufacturing Company

May 12, 1885

*********************************************************

US 328.165 Nathaniel Wheeler & Wilbur F. Dial

Rotating Loop for W&W No. 10

This invention has for its object to improve the construction and simplify the operation of the class of machine wherein a rotating loop taker enters and opens a loop of needle-thread and carries it around a bobbin, the only movement of which is that about its own axis or center and the extent of this latter movement is solely that due to the pull of the thread as the latter is consumed in the formation of the Stitch.

Assignors to the Wheeler & Wilson Manufacturing Company

October 13, 1885

*********************************************************

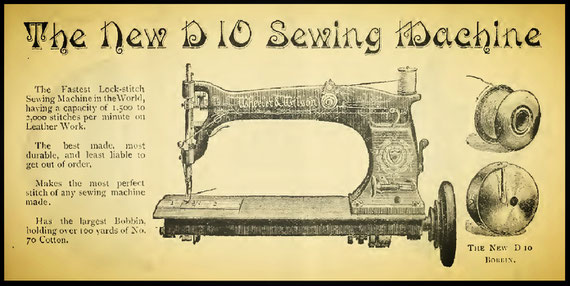

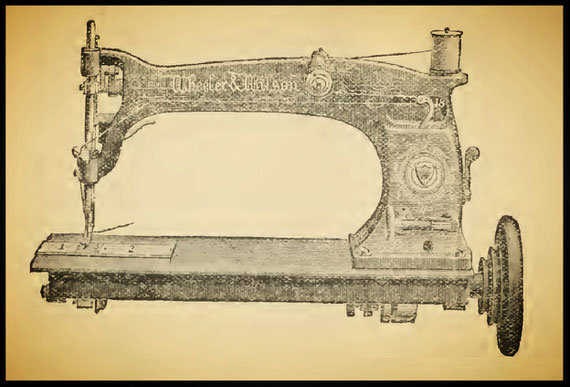

WHEELER & WILSON D 10

For Boot and Shoe Manufacturing

From 1885 To 1999 c.

New Wheeler & Wilson Machine

Unlike a number of sewing machine manufacturers the Wheeler & Wilson Manufacturing Company do not appear to be content to rest on past triumphs, but are ever on the alert to discover and introduce fresh improvements in sewing machinery.

Their latest machine is called the " D 10 " and is one of the fastest known. It is a rotary and the stitch produced differs from the ordinary lock-stitch, the upper thread being carried round the lower one in such a way as to become interlocked. The speed attained is extraordinary.

In America the " D 10 " is being used by boot and shoe manufacturers, who can work it at the rate of 1.900 stitches a minute.

Notwithstanding this great speed, the machine can be reversed almost instantaneously by means of a lever under the control of the worker. The needle used is short and can be easily set. The spool is constructed to hold 100 yards of No. 60 sewing cotton, which is a great advantage. All the parts are interchangeable. We are certain this new machine possesses several important improvements, which stamp it as being an excellent piece of mechanism. No matter what be the nature of the goods, it does its work well. The stitch is perfect on the finest linens and the heaviest work, such as leather uppers. We need not add that it is well made, as Messrs. Wheeler & Wilson have the reputation of only sending out machines of the best possible construction.

The Sewing Machine Gazette (December 1886)

New Wheeler & Wilson Spool. The Wheeler & Wilson Manufacturing Co. now supply for their new " D 10 " machine a wooden spool which holds 200 yards of cotton. This spool does away entirely with the necessity of winding bobbins. It is made by Messrs. Clark & Co., of the Anchor Thread Mills, Paisley. The invention is a great success and is specially liked by the hem-stitch trade.

The Sewing Machine Gazette (July 1887)

...The Wheeler & Wilson D 10 Automatic-Cutter Button-Hole Machine, which has the enormous speed of five holes a minute, has been altered so that it will make automatically a double row of stitches at the end of the hole In practice it is found that one girl can attend to two machines, which, together with the fact that it produces splendid work, is sufficient to account for its enormous success the past few months...

The Sewing Machine Gazette (July 1891)

*********************************************************

US PATENTS FOR W&W D 10

*********************************************************

US 331.174 Nathaniel Wheeler & Wilbur F. Dial

Feeding Mechanism for W&W D 10

Assignors to the Wheeler & Wilson Manufacturing Company

November 24, 1885

*********************************************************

US 331.183 Andrew C. Campbell

Feeding Mechanism for W&W D 10

Assignor to the Wheeler & Wilson Manufacturing Company

November 24, 1885

*********************************************************

US 345.207 Charles H. Bayley

Rotating Hook for W&W D 10 (not sure)

This invention relates to improvements in that class of sewing-machines in which a lock stitch is made by an eye-pointed needle and a rotating hook fixed to the shaft which moves it and which is adapted to take the loop of needle thread and carry it about a bobbin case containing the under or second thread.

Assignor to the Wheeler & Wilson Manufacturing Company

July 6, 1886

*********************************************************

US 350.044 Wilbur F. Dial

Loop-taker Guide W&W D 10

This invention has for its object to provide means for positively rotating a segmental loop taker in a circular race or loop-taker guide, my invention being an improvement upon the machine described in US 328.165, dated October 13, 1885, to which reference may be had. The machine described in the said patent has as the driver for the loop-taker a saddle fixed to one end of a variably - rotating shaft, the said saddle being provided at one end with a lug and at the other end with a prong, the said lug, owing to the eccentric adjustment of the loop-taker guide, being made to move out and in a notch in the loop-taker back of its point, the said lug at times pushing and at other times pulling the loop-taker in its guide.

Assignors to the Wheeler & Wilson Manufacturing Company

September 28, 1886

*********************************************************

US 352.775 Freeland W. Ostrom

Improvement in Stop-Motion Mechanism

I have herein shown my invention as applied to a sewing machine, substantially such as illustrated in my patent US 303.453, to which reference may be had.

November 16, 1886

*********************************************************

US 369.619 Aurelius Steward

Variable Motion for W&W D 10

Specification forming part of Letters Patent US 369.619, September 6, 1887

Application filed February 25, 1887. Serial No. 228.842

Assignor to the Wheeler & Wilson Manufacturing Company

September 6, 1887

*********************************************************

US 622.632 Freeland W. Ostrom

Stop Motion for W&W D 10

Assignor to the Wheeler & Wilson Manufacturing Company

April 4, 1899

*********************************************************

By 1894, the W&W Nos. 5, 7, 8 and 10 were no longer made, so customers would have been offered the No.1 (curved needle) and the New No. 4 for shirt manufacture; No.6; No.11 to special order with the Number 10 buttonhole version. All basic work could be covered by the No.9 and versions of the No.12.

by John Langdon (ISMACS)