- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

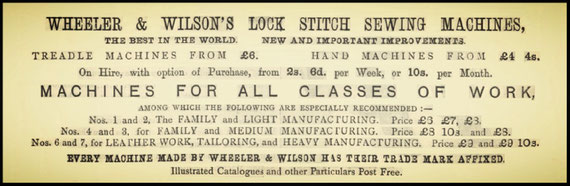

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

WHEELER & WILSON No. 8

Light Manufacturing and Family Use

From 1876 To 1887

... the Wheeler & Wilson new machine was the most completely successful, failing in nothing that was given to it. The beauty of its stitch, especially on leather, was unsurpassed and it obtained a second award "for superior quality of work in leather stitching"...

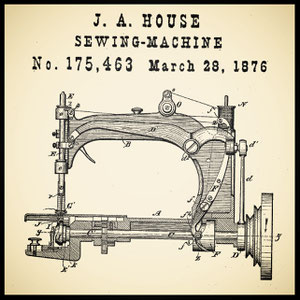

The invention more especially relates to sewing machines of the Wheeler & Wilson type, particularly adapted for sewing leather and heavy fabrics and constitutes an improvement on the machine shown and described in Letters Patent US 124.360 granted on March 5, 1872 and US 145.570, granted on December 16, 1873.

The machine is provided with a four-motion feed.

In the patents before mentioned the feed moved the fabric in the same direction as that in which the hook rotated, the bracket-arm standard and driving connections in those machines being on the left of the operator when it worked. That arrangement is now reversed and the present machine is consequently so organized that the cloth is fed in a direction opposite to that of the rotation of the hook.

In the old machines the upward and forward movements of the feed could be effected by a single cam, but such arrangement would be impracticable with the present feed.

The other details of the hook and bobbin, being similar to those shown in the former patents, require no special description here.

The presser foot mechanism is substantially the same as that shown in patent US 145.570 of December 16, 1873.

The bobbin is supplied with thread as usual. The hook is driven with a speed variable relatively to that of the driving-shaft, although completing its revolution in the same time, as explained in the former patents. The needle arm, at proper intervals, moves downward, piercing the fabric and carrying down its loop of thread to be engaged by the hook and rises quickly and pauses slightly at the end of its stroke, the take-up tightening the stitch during the latter portion of the rise of the needle and also during the first part of the descent of the needle to form the succeeding stitch, whereas, in the patents above mentioned, the pause of the needle in its upward movement took place while it was still in the fabric.

This invention relates to sewing machines of the Wheeler & Wilson class and is specially designed as an improvement upon the machines described in United States Letters Patent, US 124.360, US 145.570 and US 175.463, to which reference may be had.

The needle-operating and take-up mechanisms and the construction and operation of the rotating hook with reference to the needle, are in this present invention as in Patent US 175.463.

At the forward end of this shaft "a" is a disk, "e", provided with a crank-pin, which is connected, by means of the link "g", with a pin on a crank, "h", at the rear end of the hook-shaft "i", supported in a bearing, "j", placed out of line with the main shaft, the rotation of the latter shaft, through the link "g", imparting to the hook-shaft the variable motion substantially such as described in Patent US 124.360, wherein is employed a differential disk. The hook " f " is as commonly made.

It will be noticed that the slot in which the block or pin slides is provided with a scale, "18", to indicate different lengths of feed.

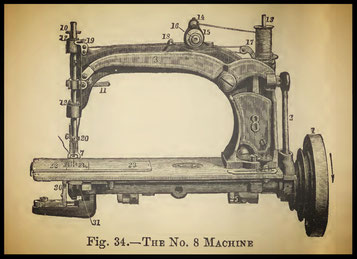

Fig. 34 represents the No. 8 machine, which is constructed with a view to give great speed and to run very lightly, for domestic use and the lighter kinds of manufacturing. The chief points of difference between it and the No. 6 or 7 machine are almost obvious on glancing at the engraving. The needle arm is moved by an eccentric and connecting rod. The take-up is pivoted at the base of the fixed arm and moved by a cam, 25. The upper tension apparatus is situated above the arm, as shown. Running from the reel, the upper thread passes from the take-up over a roller attached to the fixed arm and thence directly to the needle, the thread controller being dispensed with. The feed mechanism is of the four-motion kind, as in the other sizes of this machine and the hook and under spool are also the same. This size is especially suitable as a hand machine and is light and portable. To render it suitable for this purpose, a hand wheel, gearing in a pinion upon the spindle, is fixed to the arm and the machine is mounted in a wooden base, which, when not in use, is enclosed by a case. The stitch is regulated as to length by a thumb screw placed near to the base of the arm, as shown at 24 in Fig. 34. This screw communicates with the buttend of the feed by a rod fixed under the frame. A stitch index is provided, by which the length of stitch may be determined previous to commencing to sew. The glass presser foot is usually employed with this machine and is capable of being drawn out when required. Plate III contains the No. 8 machine dissected, showing the difference between its parts and those of the No. 6 and 7 types.

Urquhart 1881

Criticism of Mr. Urquhart's Lecture

By Rotary Shuttle

( Continued from last month )

..I call it a rotary shuttle, a hooked or barbed beak shuttle, if you like, but, most certainly, a shuttle. And why not call it a shuttle ? It answers perfectly to the formula laid down last month:

it contains the under thread; it is provided with the means of catching the loop; it is driven, with the under thread in it, completely through the loop.

These are the essential points in all shuttles and as the device in the Wheeler & Wilson's D 10 is no exception, it is, therefore, properly called a shuttle. In his next paragraph the lecturer refers to "Rotating Hooks" and more especially to the hook in the W&W No. 8 machine, the difference between which and the original Wheeler & Wilson lies, as everybody knows, in the hook having a deeper cavity for a more commodious bobbin and in the employment of an independent take-up above the work. Mr. Urquhart describes this new hook as "an improvement on Wilson's original device", but that is only a matter of opinion. The fact that almost every succeeding consignment of these machines to this country embraced some alteration in the details seems to prove that the company themselves did not think so. But whether it is an improvement or not, this, at all events, is plain to every observer in the trade, that the W&W No. 8 machine killed off the W&W No. 1 machine and now the adoption of the rotary shuttle will kill off rotating hooks altogether, I mean rotating hooks for effecting the lock-stitch, just as the Singer Company, by the introduction of their vibrating and oscillating machines, are killing off the well-known family and medium styles...

The Sewing Machine Gazette 1887

read full article

***

By 1894, the W&W Nos. 5, 7, 8 and 10 were no longer made, so customers would have been offered the No.1 (curved needle) and the 'New No. 4' for shirt manufacture; No.6; No.11 to special order with the Number 10 buttonhole version. All basic work could be covered by the No.9 and versions of the No.12.

by John Langdon (ISMACS)

Early style No. 8 with square-edge balance wheel.

DATING W&W No. 8 Machines

000....................

+ 30.000 1876

30.000....................

+ 50.000 1877

80.000....................

+ 50.000 1878

130.000....................

+ 50.000 1879

180.000....................

+ 60.000 1880

240.000....................

+ 60.000 1881

300.000....................

+ 60.000 1882

360.000....................

+ 60.000 1883

420.000....................

+ 60.000 1883

480.000....................

+ 60.000 1884

540.000....................

+ 60.000 1885

600.000....................

+ 60.000 1886

660.000....................

+ 60.000 1887

720.000....................(?)

Sources:

The Sewing Machine Gazette and Journal of Domestic Appliances

As reproduction of Historical artifacts, this works may contain errors of spelling and/or missing words and/or missing pages, poor pictures, etc.