- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

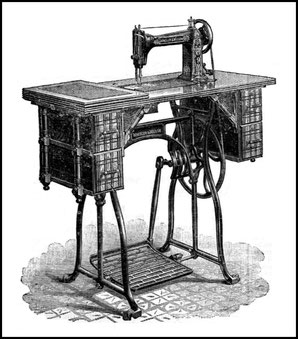

WHEELER & WILSON No. 9

From 1888 To 1905 and beyond

After considerable study and expense the company have launched upon the somewhat overcrowded sewing machine market a new invention called the No.9, which for its many merits deserves and will no doubt receive, a large share of public patronage. The Wheeler & Wilson Company long since came to the conclusion that the rotary movement is the true mechanical principle for manufacturing machines and most experts hold that this is also true as regards family machines. The Company, as is well known, have always been in favour of the rotary principle and apparently intend to stand by it. The stitch-forming mechanism of the No.9 is, therefore, similar to that of the No.8, D10 and No.12, but, as distinct from the No.8, there is no vibrating arm, two revolving shafts being used, an upper and lower, the driving pulley being attached to the former and the machine constructed on the high-arm principle. The take-up is unusually short and is placed just over the needle on the head block. The thread controller is thoroughly automatic in action and comprises several decided improvements, which contribute to the production of a stitch which is simply perfection. The driving wheel revolves in a reverse direction to the No.8.

The Sewing Machine Gazette 1888

PARIS EXPOSITION 1889

*********************************************************

W&W No. 9 US PATENTS

*********************************************************

US 420.847 Nathaniel Wheeler

Revolving Hook for sewing machines

February 4, 1890

*********************************************************

US 480.181 Wilbur F. Dial

Claim:This invention has for its object the improvement of that class of sewing mechanism wherein a circularly-moving loop-taker engages a loop of needle-thread and without passing through it casts the said loop about an under thread in a wound mass, said under thread being located within a circle traversed by the point of the loop-taker. One form of loop-taker of this class is represented in United States Patent (US 420.847), dated February 4, I890.

August 2, 1892

*********************************************************

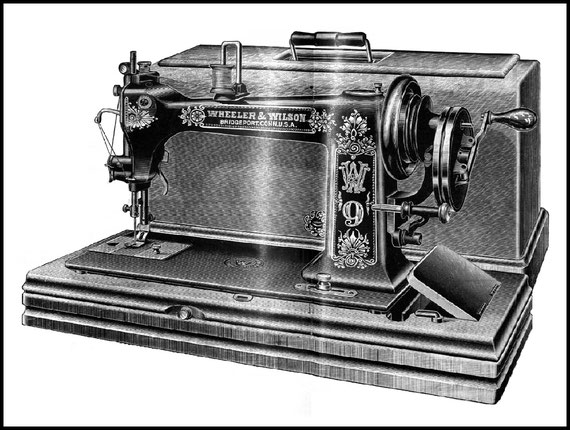

WHEELER & WILSON D 9

Exclusively for Domestic Use

From 1894-5 c.

US PATENTS ON W&W D 9 CLOTH PLATE

*********************************************************

*********************************************************

US 424.237 March 25, 1890

*********************************************************

US 386.300 July 17, 1888

*********************************************************

August 18, 1885

(no W&W patent)

December 2, 1884

US 308.711 ?

US 308.858 (Attachment for W&W No. 10) ?

October 23, 1883

May 1, 1883

note:

The W&W No.15, is the same principle as the W&W No.9, but longer, having a space under the arm of 12 inches.

THE NEW W. & W. MACHINE

A year or so ago it was decided by the Wheeler & Wilson Manufacturing Company to introduce a new hand machine, which, whilst being well up to the Company's standard of quality, should be procurable by dealers at a much lower price than has formerly been charged for any of this Company's machines. During the past month the first consignment of the new machine has arrived and we have had an opportunity of thoroughly examining both the machine and the conditions under which it is to be offered to dealers. For details as to terms we must refer our readers to the Wheeler & Wilson Manufacturing Company, 6, Paul Street, Finsbury, London, E.C. . As to the new features of the machine, we will at once give a few particulars.

Our readers will observe from our illustration that the new machine, called, by the way, the " D 9 " , bears a striking resemblance to the " No. 9 ". It is, however, somewhat smaller and lighter and the hand appliance is more compact. Although the " D 9 " can be used with a treadle, the Company specially desire to sell it as a hand machine for which it is eminently suited, being extraordinarily light and quiet.

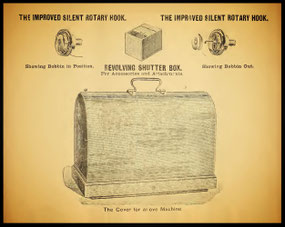

This machine is invariably supplied with a handsome walnut cover (as illustrated), which cover is held to the machine by means of four bolts, two at each end, operated by the ordinary machine key. These bolts also hold the head to the base. The accessories are kept in a roomy walnut box of a size just sufficient to go under the arm of the machine, which box has an ingenious revolving shutter, also rubber feet in order not to scratch the base. We find the upper part of the machine, so far as the feed, tension, the useful tension-release and the driving mechanism are concerned, to resemble the '' No. 9 ". The thread guide, however, is fitted to the needle-bar in a novel manner. It is attached by a screw which is independent altogether of the needle set-screw, which is a decided improvement, as mechanics will at once recognise. Then as to the needle: whilst the ordinary " No. 9 '' will answer, it is recommended to use a new needle with a flat shank, which it is only possible to set correctly. Slots are used instead of holes wherever possible to avoid trouble in threading up and a further improvement is a thread-cutter. This cutter is fitted to the front plate slide in such a manner as not to be in the way and it not only cuts the thread but holds it until required.

But it is the under-part of the machine where the greatest change has been made and, in a word, this improvement consists in adapting the mechanism of the " No.11 ", a manufacturing machine, to the " D 9 ", which is exclusively for domestic use.

Most of our readers will understand what is meant by the " No. 11 " without further details, but our illustrations will enable all in the trade to appreciate the mechanism. Mr. Joseph Powell, the representative of the manufacturers in this country, is enthusiastic over this new machine, which he considers worthy to rank among the best achievements of the Wheeler & Wilson Company and we can conscientiously support him in this opinion. We are informed that applications for agencies must be made early, as there is certain to be a rush of dealers anxious to handle it, having regard to the extraordinary terms offered to the trade. We might add that the " D 9 " is sent to dealers packed four in a case, which case is not charged for, nor is it returnable.

(May 1895)

HINTS TO SEWING MACHINE AGENTS AND DEALERS BY ONE OF THEMSELVES

How to give a lesson on a Wheeler & Wilson No. 9

In the first place, if your customer does not know how to treadle a machine, unthread the needle, take out the spool and spool-holder and raise the presser-foot, then, in the simplest possible manner, show how to treadle. When she has learned how to treadle the machine fairly well (do not thread the machine up yet), put two thicknesses of material in the machine and lower the presser foot. Then, as she further improves, gradually increase the number of thicknesses of material; insist on her frequently stopping and restarting the machine till she has mastered the treadling. Now show her how to thread the machine up at the top and to place the spool in the spool-holder. With regard to putting the spool in the spool-holder correctly, you can scarcely use too many illustrations in making it quite clear how the spool should revolve in the spool holder. Place the spool in the spool-holder so that the cotton when drawn out causes the spool to revolve from you. Make that part of your instructions clear by pointing out that the spool must revolve the same way as the hands move on the clock face (she will always remember that illustration), or turn the balance wheel of machine slowly from you. Draw her attention to the rotating hook and explain that the point of the hook always moves towards you. Then show that the spool must always be so placed in the spool-holder that the spool will move in the opposite direction to the rotating hook when the balance wheel of machine is turned from you.

Setting the Needle.—Set the needle with its long groove towards the right, turn the machine head over, draw out the left hand slide and show how the loop is being formed as the rotating hook approaches the needle. Turn the short groove of needle slightly from you and let her see that that alteration causes the loop to lean towards the hook. Now turn the short groove of needle slightly towards you and show that the alteration causes the loop to lean from the hook. Explain that whether using cotton, silk, or thread, the needle must be so set that the loop is thrown straight out. She will then clearly understand how to set the needle so that the machine is least liable to slip stitches.

Needles, Cotton and Tensions.—Do not forget to point out the importance of choosing a suitable size needle and cotton for the material to be sewn. Draw her attention to information given in the Instruction Book on this point. For general sewing recommend a No. 5 needle and 50 or 40 cotton. The finer the needle and cotton used the more beautiful the stitching will be. If a too coarse needle is used it will be apt to cut the material and slip stitches. If the needle makes a larger puncture in the material than the cotton can possibly fill up, the stitching is not only not so strong, but is also more unsightly. If the needle is too fine for the cotton, it is also liable to slip stitches and break the top cotton. If the needle is too fine for the cotton it does not make a hole sufficiently large for the lock to be drawn easily into the centre of the goods, therefore the tension must be tightened, which puts an unnecessary amount of strain on the cotton, the material and the machine. There is little or no difficulty in making perfect stitching with comparatively light tensions when suitable needles and cotton are used. When the tensions are too tight, the elasticity of the cotton is taken out of it before it enters the material, consequently the stitching in that case is more liable to crack. To make the stitching almost as elastic as the material, put a little more pressure on presser-foot, then place your material under the foot and, at the same time as you are guiding the work, put a fair amount of restraint on it, and in that way you keep the material stretched while the stitches are being formed, thus making the stitching almost as elastic as the material. When making tucks or stitching on trimmings, explain the advantage of making a larger stitch than usual and slacking the top tension, by so doing the machine work can be drawn out much easier and quicker than even handwork. Put on a good-sized stitch and show which is the top and which is the bottom cotton. Also carefully explain how, when using two different coloured cottons, the tension can be so adjusted that only the cotton that is used to match the material can be seen on the outer part of the garment. This is very important. Do not run the machine after you have reached the end of a seam, &c., nor with presser-foot down, except when sewing, as it scratches to the foot and blunts the feed.

Oiling and Cleaning the Machine.—Advise the use of only good oil and point out all the places that require oiling. It is important that the oil holes, rotating hook, spool-holder and spools should be kept clean. It is desirable that the face-plate should occasionally be taken off so that the needle bar " link " can be oiled. The throat-plate should frequently be taken off and the feed points cleaned. Explain that the bevelled part of plate should be put into its place first.

General Remarks.—Several of the hints given apply to Jones' and Bradbury's on No. 9 principle and other kinds of machines. The remarks on the " spool and spool-holder" also apply to the Nos. 6, 7, 8, and 10 machines. I have found several people who were prejudiced against W. & W. machines because the stitching was not satisfactory and the reason was they did not know that there was a right way and a wrong one for the spool to revolve. When pointing out the importance of keeping the material stretched while the stitches were being formed, I have been rather surprised to hear even first-class dressmakers say, '' I never thought of that ".

We too frequently make the mistake of crediting other people with knowing almost as much as we do ourselves, which is not, or certainly ought not to be, true.

The more pains you take to make the above hints clear to your customer the more she will be delighted with the wondrous power and adaptability of the machine and will have pleasure in recommending it and you to her neighbours and friends. The object of the machinist should be to produce the most perfect work with the least possible strain alike on the cotton, the material and the machine and your object should be to teach her all you know that will help her to realise that object.

by A. Cromack (June 1895)

Sources:

The Sewing Machine Gazette and Journal of Domestic Appliances

As reproduction of Historical artifacts, this works may contain errors of spelling and/or missing words and/or missing pages, poor pictures, &c.