- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

Information on Empire Sewing Machine Company's web pages, regarding the Juengst family and their various companies, factories name and their location, including those links to Remington S.M. Co., come from different sources, appear to present some discrepancies and consequently arduous to line up dates.

George Juengst

and Family

Augustus “Gus” was the third son of George Juengst Sr., a German immigrant who, with his brothers Peter and Louis, founded the Empire Sewing Machine Company in Amawalk (Somers), N.Y. near the end of the Civil War.

Part of the system's Croton Watershed, it was formed by impounding the middle of the Muscoot River, one of the tributaries of the Croton River. This reservoir was put into service in 1897 and was named after the original community of Amawalk, New York, which was inundated by the reservoir and relocated near the dam.

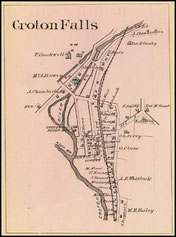

In 1871, when the Aqueduct Commission claimed the waters of the Muscoot River, the Juengsts no longer had enough water to power their mills. George Juengst Sr. then founded, with his sons George Jr. and Charles, a machine shop in a building he leased from Joel Purdy in Croton Falls (Somers).

George Juengst & Sons quickly expanded to larger buildings further up the river. With George Sr. and Jr. the engineers and Charles the inventor, the family business flourished, producing finished tools and machines that were sent to all parts of the U.S. and abroad. With power from the river, they also founded the George Juengst & Sons Lighting Company in 1897, which produced and supplied the first electric power in the area. Gus was superintendent of the electric plant.

In 1906 they extended their electrical service to Somers, then Lewisboro, Bedford Village and Cross River.

This American Craftsman or Bungalow style residence, built for Gus and his wife Harriet in 1912, features a shallow hip roof, with dormer and widely overhanging eaves to form a porch at the front supported by heavy stone pillars. Natural materials are emphasized: cobblestone, wood shingles, earth-tone colors, oak parquet floors and ash, oak and cypress woodwork and wainscoting. There are built-ins, inglenooks, glass and lighting features in the Arts and Crafts style.

Unfortunately, Gus lived here for only six years before he was killed in a freak accident at the electric plant. He and a colleague had repaired a break and his friend, Henry Myers, went to restore the power. Gus noticed a wire had fallen on an automobile. He didn’t know his friend had turned the power back on and was electrocuted while removing the wire. The Brewster Standard reported on the inexpressible horror and sadness of the community. Harriet died the following year.

Historic Landmarks of the Town of North Salem, New York

Geo. Juengst & Sons

Croton Falls, NY, U.S.A.

Manufacturer Class: Metal Working Machinery

Juengsts' Patents

*********************************************************

US 15.697 George Juengst

Reversing-Gear

September 9, 1856

*********************************************************

US 18.908 George Juengst

Dynamo-meter

December 22, 1857

*********************************************************

US 27.132 George Juengst

Sewing Machine

...what I claim as new and desire to secure by Letters Patent:

1. The combination of the rotating shafts F K, one of them carrying a revolving arm J and the other two revolving cranks G H, when the said shafts, arm and cranks are arranged and operate as herein shown and described.

2. The shuttle-driver, with its jointed horn i, ear r and spring p, applied and operating in combination with the guide m, n, o on one side of the shuttle-race and operating substantially as herein described.

February 14, 1860

*********************************************************

US 28.869 George Juengst

Sewing Machine Shuttle

In sewing machine shuttles the bobbin is generally made with a male center at each end and held in place between two female centers provided in the shell of the shuttle and one of the latter is made movable for the purpose of permitting the introduction and removal of the bobbin and held up to the bobbin by means of a spring. This movable center and its spring are generally introduced from the exterior of the shell through an opening which extends right through the heel thereof, but which, after the center and the spring are inserted, is closed by a plug inserted in from the exterior and secured by soldering. Shuttles have also been formed with the movable spring-center in the point; but the same was inserted when being manufactured and no provision was made for introducing a new spring in case injury to that before inserted, or when one of a different strength was desired. My said invention consists in a movable bush, through which the center passes and which bush fills up the parallel hole containing the spring and is held in place by a clamping screw.

June 26, 1860

*********************************************************

GB 2.340 Joseph McCrossan

Sewing Machine

To Joseph McCrossan, of Glasgow, in the county of Lanark, North Britain, Merchant, for improvements in sewing machines. A communication to him from abroad by George Juengst, residing at New York. Letters Patent sealed

September 26, 1860

*********************************************************

US 31.691 George Juengst

Sewing Machine

My improvements relate to that class of sewing machines where the straight needle is used with the shuttle and the feed-wheel and they have reference to the means for giving motion to the needle, specially regarding the formation and condition of the loop of the needle's thread, to means for taking up the thread and tightening the stitch and to means for making and regulating the feed.

Assignor to J. McCrossan and T. J. McArthur

March 12, 1861

*********************************************************

US 135.125 George Juengst

Bobbins for Sewing Machine Shuttles

A bobbin for the shuttle of a sewing machine requires to be very light and to occupy as little space as possible, so that the bobbin will hold a large amount of thread and not materially increase the weight of the shuttle. Bobbins have been made with a steel spindle and brass heads, that have been forced upon the ends of this spindle. In some instances the heads and the spindles have been soldered together. This involves considerable time and expense. My invention consists in a sewing machine bobbin made with a wire spindle and sheet metal heads that are secured to the spindle by the thin sheet metal of the heads being pressed into the metal of the spindle sufficiently to embed itself and thereby the heads are held on very firmly and can be made of very thin metal. This bobbin is a new article will hold as much thread as can be introduced into the space provided and when the bobbin is empty it may be thrown away, its cost being so small.

January 21, 1873

*********************************************************

US 171.572 George Juengst

Mechanical Movement

December 28, 1875

*********************************************************

US 173.301 George Juengst

Mechanical Movement

February 8, 1876

*********************************************************

US 209.970 George Juengst & Charles A. Juengst

Meat Chopping Machine

November 19, 1878

*********************************************************

US 209.971 George Juengst & Charles Bernhard

Fire-Escape

November 19, 1878

*********************************************************

CA 10.560 George Juengst

October 18, 1879

*********************************************************

US 228.820 George Juengst

Sewing Machine

This invention is, in part, applicable to all kinds of sewing machines, but some features of it are or may be limited in their application to machines of one or more particular classes; but the whole invention is capable of embodiment in a single machine, as illustrated in the accompanying drawings. One part of my invention relates to the take-up for taking up the needle-thread. The kind of take-up which employ is that in which the principal element is a vibrating arm or lever and this part of my invention consists in a novel construction and arrangement of the said lever and novel means of operating and controlling the operation of the same, whereby its efficiency is increased. Another part of my invention relates to the mechanism for feeding the cloth or material to be sewed. This part of my invention consists in a novel system of separately-adjust able fulcrum-slides and fulcrums for separately varying the movements of the feed-lever both horizontally and vertically, and thereby varying the relative horizontal and vertical movements of the feed-dog. This improvement in the feeding mechanism is applicable to sewing machines of various kinds. Another part of my invention relates to that class of sewing machines in which a loose bobbin-holder or thread-case containing the secondary or locking thread is arranged within an oscillating hook, which is employed to extend the loop of the needle-thread and it consists in a combination of the feeding-dog with the bobbin-holder, whereby the feeding dog in its downward motion is made to press on the bobbin-holder and so made to press the latter away from the position to which it has been brought in the tightening of the last previously-formed stitch, so that when the dog rises again the bobbin-holder may be left free for the passage of the loop of the needle-thread over or around the bobbin. This part of my invention also embraces means of providing for a regulated pressure of the feeding-dog.

June 15, 1880

*********************************************************

US 305.520 George Juengst

Shaping and Planing Machine

September 23, 1884

*********************************************************

US 309.857 Charles A. Juengst & George Juengst Jr.

Variable Reciprocating Planer-Motion

December 30, 1884

*********************************************************

US 372.805 George Juengst Sr.

Telegraphic Transmitter

November 8, 1887

*********************************************************

US 436.139 Charles A. Juengst

Shaping and Slotting Machine

September 09, 1890

*********************************************************

US 617.532 Charles A. Juengst

Metal-Planer

January 10, 1899

*********************************************************

US 846.923 Charles A. Juengst

Signature-Conveying and Wire-Stitching Machines

My invention relates to devices for wire stitching or stapling groups of superimposed signatures or sheets in forming pamphlets, magazines, &c. and it relates also to devices coacting therewith and for delivering thereto is the said groups of signatures or sheets as collated by a signature-gathering machine, the object of my invention being to group in one machine the devices performing these functions, so that the work may be quickly and economically performed and without the signatures or sheets being handled by an attendant in transit from the gathering-machine to and through the wire-stitching machine.

March 12, 1907

Reissued

US RE 13.967 August 24, 1915

*********************************************************

US RE 13.967 Charles A. Juengst

Signature-Conveying and Wire-Stitching Machines

August 24, 1915

Specification forming part of Letters Patent

US 846.923 March 12, 1907

*********************************************************

US 1.346.799 Charles A. Juengst

Book or Pamphlet Covering Machine

Croton Falls, New York

Assignor to himself and George Juengst Jr.,

doing business under the name of George Juengst & Sons

Application filed March 19, 1910 Serial No. 550.305

Renewed November 17, 1919 Serial No. 338.527

July 13, 1920

*********************************************************

In the present state of the art of sewing by machinery there are two fundamental mechanical modes of actuating the needle and shuttle in executing sewing with those instruments. In one (the earlier mode) the said sewing instruments are moved or operated, partly or wholly, by some form of what are known in mechanics as "cams". Such are called "cam machines" and of these a proper example are those made by Howe and by Singer. In the other and more modern mode all the required movements of the needle and shuttle are accomplished by various combinations of cranks and links. The latter are represented by the machines and improvements patented by Earle Harry Smith, May 4, 1858 and George Juengst, 1860 and are called "crank-machines".

Specification forming part of Letters Patent

...In the year 1854 he Earle Harry Smith exhibited to the editors of this journal a shuttle machine with his new combination of movements, the needle being worked as it never had been before in such a machine, viz., by a true eccentric, imparting an easy and continuous motion; while the shuttle, driven by a crank pin, also had a continuous and uninterrupted movement, a combination altogether unlike any sewing machine then known while the whole construction was exceeding novel an very simple. This, we believe, was the first shuttle sewing machine ever made having continuous or crank motions. Since then Mr. Smith has obtained, in all, eight patents for improvements looking to the perfection of this class of machines, in nearly all of which the continuous or crank motion prevails throughout...

Scientific American September 16, 1865

Croton Falls Lighting Corporation

This company was incorporated on April 13, 1923, under the laws of the State of New York. Its incorporation was for the purpose of acquiring the electrical plant and property of George Juengst & Sons, located at Croton Falls, N. Y. Application for authority to acquire the aforementioned property was filed January 26, 1925, with the Public Service Commission of the State of New York. The application, however, was superseded by one filed under date of January 11, 1926, providing for the transfer of the property of George Juengst & Sons to the Harlem Valley Electric Corporation.

For the purpose of this report the property is shown transferred from the Croton Falls Lighting Corporation and not from George Juengst & Sons to the Harlem Valley Electric Corporation. The company distributed electricity in the towns of Southeast and Carmel, Putnam County and the towns of Somers, Yorktown, North Salem, Lewisboro and Bedford, Westchester County, N. Y. Control of this company was acquired by the Associated Gas & Electric Co. in October, 1924, as the result of a contract dated October 22, 1924, between Charles A. Juengst, Magdalene Juengst and Walter W. Taylor, the latter acting for the Associated System. The Croton Falls Lighting Corporation was merged into the Harlem Valley Electric Corporation as at December 31, 1924.

William George Juengst and Olga Helmetz had child:

Peter Juengst was born in 1815 in Germany. His first wife was Margaret.

Their kids were:

1. George Juengst Sr. born in 1829 in Germany and died in 1905 in Croton Falls, N.Y. He married Josephine Rosenberg in 1856 about.

born Feb. 1, 1828; d. Jan. 6, 1905 in Croton Falls, buried in Ivandell Cemetery, Somers, N.Y. He Married Josephine Rosenberg and had two children, Charles A. and George Jr. Josephine died and he married her sister Marie Anna Rosenberg and they had two children, Magdalena and Augustus.

Their kids were:

a. Charles A. Juengst born in January 2, 1859 N.Y. and died in 1931.

b. George Juengst Jr. born in August 24, 1860 and died after 1925. He married in October 3, 1888 or 1889 to Katherine (Kate) M. Decker born in 1869.

Their kids were:

Charles 11, George 10, Magdaline. The kids were born in NY.

c. Magdaline (Lena) Juengst born in January 1869.

d. Augustus A. (Gus) Juengst born in July 1874. He married Harriet. He died after 1912.

2. Daniel Juengst born in 1840 in Kassel Germany possibly.

3. Louis Juengst

4. Margarete Juengst

5. Christine Juengst

Peter Juengst born 1815 in Germany. His second wife was Wilhelmina (Philomena) Wilholm. Their kids were:

1. Charles Juengst born about 1840

2. Henry Juengst born 1846

3. William Juengst born June 4, 1850

George Juengst had quite a machine tool plant in the Village of Croton Falls, NY prior to the development of the NYC Water Supply's Croton Reservoir. Juengst had a sizeable shop, and had his own hydroelectric generating plant. Power from Juengst's plant was sold to local homes. When the Croton Reservoir was built, a large area of land was taken by eminent domain for the reservoir. Juengst's shop was in that area, and the shop was ultimately razed to clear the land for the flooding of the reservoir. In the present times, there is a "Juengstville Road" down in Westchester County near the Croton Reservoir. Once the Croton Reservoir construction began, Juengst was forced to give up his shop and was given "fair market value" according to NY City Board of Water Supply land assessors. Most people in the NYC Watershed area got very little for their lands and buildings and businesses or farms. George Juengst himself died somewhere around 1915. I would guess that once the NYC Watershed had condemned and taken his shop, the machinery in it was liquidated at auction and Juengst never re-started his machine tool firm in any other location. I think Juengst shapers are fairly rare machines, with Juengst not building very many shapers and then having their best years ended by the seizing of their shop and lands for the reservoir. As I recall reading, Junegst had their own foundry as well as the machine shop.

having their own hydro electric plant, they had a mill dam on the Croton River. Since the NYC Watershed was going to be building a bigger dam and impounding a lot more water, Juengst was squarely in the way and had to go.

The Croton watershed and final developments were probably completed some time around 1900-1910, to put things into some kind of time frame.

By Joe Michaels Diamond

-----------------------------------------------------------------

Juengst & Sons

Hydro Plant at Croton Falls, N.Y., Brewster District

HISTORY AND PRESENT USAGE

...In 1884, the George Juengst family bought the property and water rights to the flow of the East Branch of the Croton River. The buildings involved. were a grist mill, a saw mill, a paper mill and a foundry. The family firm, George Juengst & Sons, generated electrical power needs not only of adjacent industry but also of nearby communities· in northern Westchester and southern Putnam counties. On February 25, 1911, Justice Martin J. Keogh rendered a decision granting New York City "the right to divert or take from the East Branch of the Croton River all the waters of said East Branch of the Croton River and all tributaries thereof in excess of thirty million gallons per day. In compensation for this ruling, Judge Keogh ruled that Juengst & Sons be awarded a sum of $118.732 from the city. New York City appealed this ruling in 1913, but the order was affirmed upon re-argument. In 1926, a contract was signed between the Juengst interests and the Harlem Valley Electric Corporation. Juengst & Sons agreed to sell the balance of the power generated but not consumed at the site. New York State Electric & Gas later signed a power purchase contract with Juengst Company. Tests conducted at the Juengst & Sons Hydro Plant by representatives of New York State Electric & Gas Corporation (NYSE&G) and Juengst & Sons in October 1943 determined that the maximum output the plant could generate was 270 kilowatts. These tests were part of a study by NYSE&G to investigate ways in which the operating costs could be lowered. This led to a proposal that the plant should be semi-automated. The study summary begins, ''The average yearly output of the Juengst & Sons Hydro Plant over the last 15 years was 2.096.115 kwh. In 1946, it was 2.113.400 kwh. This output can be obtained with semi-automatic operation. 'This recommendation was not followed; Juengst & Sons ceased operation of the hydro plant in 1956. Walter T. Phillips, Jr., bought the property and water rights of the site on October 28, 1969. The site is leased to the Salem Energy Corporation. The controlling interest in this firm is owned by the Phillips family and Mr. Phillips has designated Salem Energy Corporation as the site developer. The limited reservoir storage formed by the Phillips Dam is not presently used for any purpose...

...The results of this study show that for the period from 1927 to 1955, during which time the Juengst & Sons Hydro Plant was in operation and for which simulated flows are available, the average monthly flow varied between 46 and 400 cubic feet per second with the average yearly values ranging from 77 to 168 cubic feet per second. For the period after 1955 the average monthly flows varied from 11 to 300 cubic feet per second with the average yearly values ranging from 70 to 153 cubic feet per second...

PHILLIPS HYDROELECTRIC PROJECT

FINAL REPORT

June 1979

-----------------------------------------------------------------