- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

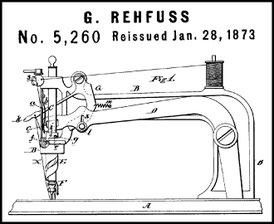

ISRAEL M. ROSE

*********************************************************

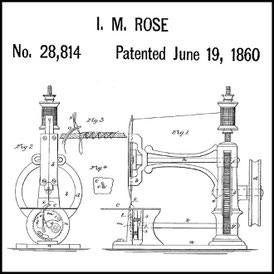

US 28.814 Israel M. Rose

Button-Hole Sewing Machine Two Threads

The nature of my said invention consists in the combination of a revolving hook, bobbin and reciprocating needle with an eye-pointed needle that perforates the cloth in such a manner that the under thread is interlaced or concatenated with needle-thread at the surface of the goods and the loop of needle-thread being passed around the bobbin of second thread prevents the loop of needle-thread drawing up through the cloth, so that I perform the operation of working a button-hole by the combined shuttle and double-loop stitch, or in any similar operation to that of making a button-hole may be performed in my said machine.

Assignor to Jno. R. Morrell

June 19, 1860

*********************************************************

US 31.628 Israel M. Rose

Button-Hole Sewing Machine One Thread

My invention relates to such a modification of the common sewing machine as to enable the operator, by means thereof, to work a button-hole in cloth with the ordinary hand sewing button-hole stitch made with a single thread. The contrivance can readily be attached to many of the machines now generally in use.

March 5, 1861

*********************************************************

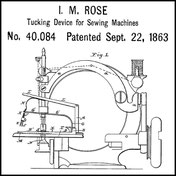

US 40.084 Israel M. Rose

Tucking Device for Sewing Machine

Tucks were heretofore determined on sewing machines by some piercing or marking instrument vibrated or held to bear with constant pressure upon the cloth in a line adjustable at the pleasure of the operator. The objections to the former were that the cloth was either injured by the large holes made by the piercing-needle or the holes were so small as to leave almost imperceptible marks and that in either instance it was necessary care fully to crimp and fold the cloth by following the trace of the holes. Fine fabrics were particularly liable to injury by this mode of marking tucks and it had to be abandoned. The objections to the marking of tucks by means of an instrument constantly pressing on the material are still more serious. It will be understood that the pressure to produce a pencil-mark on or a permanent depression or crease in the cloth is by no means inconsiderable. Now, if the material to be operated upon be limber, the tendency is to drag it by the feed and cause a tuck-mark to be produced, which will not be in a line parallel with the seam.

Assignor to J. Wilcox

September 22, 1863

Reissued

December 1, 1868 Henry W. Fuller US RE 3.218

Assignee, by Mesne Assignments of Israel M. Rose

May 21, 1878 Isaac W. Barnum US RE 8.236

Assignee, by Mesne Assignments, of Israel M. Rose

This is Israel M. Rose's tuckmarker, originally assigned to J Willcox in 1863. When it was re-issued in 1878 it was under the name of Isaac W. Barnum, the attachment maker. It was this re-issue (US RE 8.236) that required many tucker makers, including Goodrich, to take out licenses.

*********************************************************

US RE 3.218 Henry W. Fuller

Tuck-Creasing Attachments for Sewing Machine

(Guide & Hemmer)

Previous to this invention fabrics were marked or creased by means of a protuberance or point and a notch or indentation caused to impinge upon the fabric from opposite sides thereof. That mode of marking or creasing is open to the objection that fine goods will sometimes be cut by the marking operation, while on heavy or flimsy goods the crease is often insufficiently defined, which notch and point are separately adjustable to each other, as well as to the sewing machine needle. By the invention herein described marks or ridges (and obversely creases) are formed in the fabric by a succession of nips or pinches thereof, while it has motion imparted to it in line with the crease in any convenient manner, but usually the feed mechanism of a sewing machine, for which it is intended to be used as an attachment and said process of nipping or pinching is designed to obviate the objections aforesaid, which are attached to other tuck-markers and produce a more efficient instrument. The said invention comprises the use of jaws, which are caused to descend with more or less force or pressure on the fabric while open and then in being closed are capable of seizing a portion of such fabric and compressing the same tightly, such fabric being properly supported against the force of said jaws and which operation, being repeated while the fabric is moved along, produces the required ridge or crease, in line of which the fabric will naturally fold to facilitate the forming of a tuck or tucks and said invention also comprises certain details of construction, arrangement and combination to adapt tuck markers for use in connection with sewing machines and forming a tuck-creasing mechanism having an upper and under part connected and together adjustable as to its relation with the needle of a sewing machine and operated by a sewing machine.

Assignee of Israel M. Rose

(Israel M. Rose assignor to Henry W. Fuller)

December 1, 1868

Specification forming part of Letters Patent

US 40.084 Israel M. Rose September 22, 1863

*********************************************************

US 103.664 Israel M. Rose

Sewing Machine Needle for Embroidering

My invention relates to the production of an embroidery-stitch in which a separate thread, which does not pass through the cloth or fabric to be embroidered, is used as the embroidery-thread and is retained in place upon the surface of the fabric by threads, which produce an ordinary sewing stitch. It is alike applicable to single and to double thread sewing machines.

May 31, 1870

*********************************************************

US 136.098 Israel M. Rose

Embroidering Attachment for Sewing Machine

This invention relates to a new attachment to the presser-foot of a sewing machine for the purpose of laying an embroidery-thread upon the fabric which is subjected to the process of sewing and stitching said embroidery-thread down upon said fabric by means of an ordinary needle and thread without causing the embroidery-thread to pass through the fabric, leaving the same entirely upon the surface of such fabric.

February 18, 1873

Reissued

June 1, 1875 US RE 6.473

*********************************************************

US RE 6.473 Israel M. Rose

Embroidering Attachment for Sewing Machine

This invention consists in a thread-enchaining device for the production of an enchained embroidery-thread, which is laid in the form of a braid upon the surface of the fabric to be embroidered, such enchained thread or braid not passing through the fabric, but being secured thereon by stitching it to the surface thereof. This thread-enchaining device is mainly composed of a vibrating needle, operating in combination with a presser-foot and feeding mechanism, said needle constituting an embroidery-thread carrier, which has a vibratory motion in line of the length of the braid or enchained stitch and, as an attachment to a sewing machine, may, for convenience sake, be operated by the needle-bar thereof, but the action of which is in dependent of that of the sewing-needle used to stitch or sew the enchained embroidery stitch on the surface of the fabric.

Assignor, by Mesne Assignments, to Joseph J. West

June 1, 1875

*********************************************************

US RE 8.236 Isaac W. Barnum

Tuck-creasing Attachment for Sewing Machine

Tucks were heretofore determined on sewing machines by some piercing or marking instrument, vibrated or held to bear with constant pressure upon the cloth in a line adjustable at the pleasure of the operator. The objections to the former were that the cloth was either injured by the large holes made by the piercing-needle, or the holes were so small as to leave almost imperceptible marks and that in either instance it was necessary carefully to crimp and fold the cloth by following the trace of the holes. Fine fabrics were particularly liable to injury by this mode of marking tucks and it had to be abandoned. The objections to the marking of tucks by means of an instrument constantly pressing on the material are still more serious. It will be understood that the pressure to produce a pencil-mark on, or a permanent depression or crease in, the cloth is by no means inconsiderable. Now, if the material to be operated upon be limber, the tendency is to drag it by the feed and cause a tuck-mark to be produced which will not be in a line parallel with the seam. To obviate these and other defects in tucking-gages heretofore in use is the object of the invention and it consists in a mechanism, actuated by the sewing machine, intermittent in its operation and pinching the cloth at regular intervals and in unison. With the action of the machine, so as to leave a perfect ridge, in conformity with which the cloth will naturally fold to form a tuck.

Assignee, by Mesne Assignments, of Israel M. Rose

May 21, 1878

Specification forming part of Letters Patent

US 40.084 Israel M. Rose September 22, 1863

*********************************************************

US 662.629 Israel M. Rose

Grinding and Sharpening Devices

November 27, 1900

*********************************************************

US 719.880 Israel M. Rose

Grinding and Sharpening Devices

February 3, 1903

*********************************************************

US 730.706 Israel M. Rose

Grinding and Sharpening Devices

June 9, 1903

*********************************************************

US 757.843 Israel M. Rose

Grinding and Sharpening Devices

April 19, 1904

*********************************************************

US 865.802 Israel M. Rose

Automatic Lighting Device

September 10, 1907

*********************************************************

*********************************************************

Israel M. Rose's Canadian Patents

*********************************************************

CA 3.187 Israel M. Rose

Embroidering Attachment for Sewing Machine

March 12, 1874

*********************************************************

CA 7.393 Israel M. Rose

Embroidering Attachment for Sewing Machine

April 27, 1877

*********************************************************

CA 14.807 Israel M. Rose

Lighting Mechanism for Gas Lamps

May 22, 1882

*********************************************************