- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

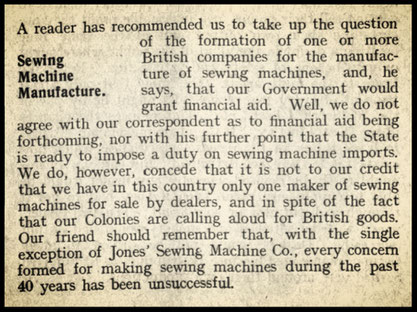

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

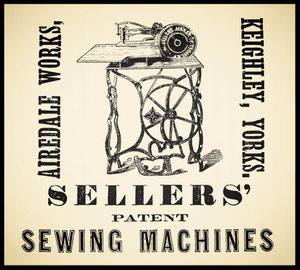

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

CHRONOLOGICAL HISTORY OF BRITISH SEWING MACHINES PATENTS

PART 2

from 1852 to 1884

************************1852************************

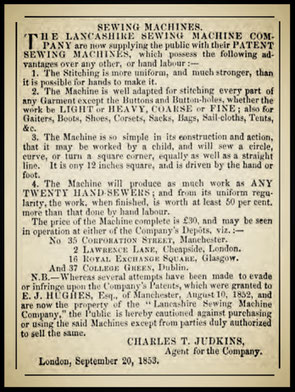

...The man to whom is due the credit of introducing the first practical sewing machine into England and with that first of necessaries a practical feed motion, was not Elias Howe and was not William Thomas but was Charles Tiot Judkins, an American located in Manchester who was the proprietor of the patent taken out by Edward Joseph Hughes, August 10, 1852 (GB 14.256/1852) and which included in its specification the machines known in America as the Grover & Baker and the Singer Manufacturing or No. 2 machine. To the former was given the name of the " Lancashire " and it is known by it to this day...

William Newton Wilson (Jan. 1892)

Edward Joseph Hughes

GB 14.256 (August 10, 1852)

(Charles Tiot Judkins)

Machinery for stitching, either plain or ornamentally.

...which included in its specification the machines known in America as the Grover & Baker and the Singer Manufacturing or No. 2 machine. To the former was given the name of the " Lancashire " and it is known by it to this day....

William Newton Wilson (Jan. 1892)

Four legs, needle & shuttle, two threads, lock stitch sewing machine

...but the introduction of the Hughes Patent of 1852 with its four motion feed threw new light upon the subject...

*********************************************************

Auguste Edouard Loradoux Bellford

GB 347 (October 12, 1852)

An invention for improvements in sewing cloth and other materials. A communication. Letters Patent sealed.

...This machine needs no explanation, it being merely a reproduction of the oblique double needle machine, already described in the matter referring to Mr.

Hughes's third machine...

*********************************************************

William Edward Newton

GB 14.328 (October 19, 1852)

Machinery or apparatus for sewing double-looped stitches

A grant unto William Edward Newton, of 66, Chancery Lane, in the county of Middlesex, civil engineer, for improvements in machinery or apparatus for sewing; a communication; 6 months.

*********************************************************

William Mason

************************1853************************

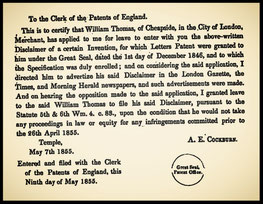

Alfred Vincent Newton

GB 124 - 1853 (January 18, 1853)

Alfred Vincent Newton of the Office for Patents, 66, Chancery Lane, in the County of Middlesex, Mechanical Draughtsman, for an invention for an improved sewing machine. A communication. Letters Patent sealed.

?

...A patent was taken out in 1853 by Alfred Vincent Newton on behalf of Singer & Co. It does not say so, but the disclaimer subsequently taken out in the name of Edward Clark, the moneyed partner of I. M. Singer and who set that gentleman on his feet, proves the connection as well as words could do it. This patent claimed a single thread machine and it also described and claimed that to which I. M. Singer attached far greater importance, viz., a spring take up which at the proper time held the thread taut in the eye of the needle. This was no doubt a valuable improvement at the time and is shown as applied in the Singer No. 2 Manufacturing Machine...

William Newton Wilson (1892)

*********************************************************

GB 1.026 (April 27, 1853)

*********************************************************

IN AMERICA

In the United States, on May 18, 1853, Elias Howe granted his first royalty license to Wheeler, Wilson & Company. Within a few months licenses were also granted to Grover & Baker; A. Bartholf; Nichols & Bliss; J. A. Lerow; Woolridge, Keene, and Moore and A. B. Howe, the brother of Elias.

...An early advertisement of sewing machines, published by I. M. Singer & Co., in a Boston news paper in 1851, attracted the attention of a young shoemaker, John Brooks Nichols, of Lynn. He was born in Wakefield, February 8, 1823. He learned the trade of shoe cutting of his cousin Thomas Bancroft, who had a shop in the basement of the Congregational church close by Lynn Common. After two years as a shoe cutter, he bought a retail store in Cambridge. This venture failed. Then he saw the advertisement of the sewing machines. Mr. Nichols, an ambitious young man, was seeking some opening with a bright future. He decided that the sewing machine would become of great value. So he bought one of the first lot of 25 machines that I. M. Singer & Co. made.

This machine, Mr. Nichols set up in a shop on Sudbury Street, Boston. He established a contract stitching business, stitching pantaloons on the machine. At the time, the sewing machine had not been perfected for use in stitching leather. Mr. Nichols, a shoemaker by trade, naturally wondered why the machine couldn’t be made to stitch leather. He began to experiment, using scraps of kid leather that he brought from Lynn shoe factories.

He found that his sewing machine wouldn’t stitch leather neatly because the needle was bigger than the thread. The seams were loose and the stitches coarse. But he was of the opinion that his machine could be made to stitch leather as nicely as did the “binders.” To make it do so, he got around to his shop one and one-half hours ahead of time in the morning, and he left it one and one-half hours late, putting in the extra time in his attempts to make his machine stitch leather.

Finding that the needle was too large, he went to the needle manufacturers and got them to make needles of new shapes and sizes. These needles he filed, and even smoothed down with emery paper to get them of the desired small size. He also went to the manufacturers of silk and cotton threads, and got them to make new kinds of thread for his experiments. After months of patient labour, he succeeded in stitching leather on the machine so that its stitches compared favorably with the stitches of the shoe binders. I. M. Singer & Co. undertook to put onto the market machines for stitching shoes.

They sold to three Lynn manufacturers (Scudder Moore, John Wooldredge and Walter Keene), rights to use the machine for stitching leather in Essex County. Mr. Nichols became instructor of operators on the machines used by these ‘firms. He was paid $3 a day for his services, which was twice the wage that he ever received before, and a wonderfully high wage for the time.

Mr. Nichols decided that he would himself start a contract stitching shop. The three manufacturers who had purchased the exclusive rights to use Singer machines for stitching shoes in Essex County protested to the Singer Co. against Mr. Nichols starting in business. The Singer Co. declined to let Mr. Nichols have any machines. But he secured a Singer machine that the Singer Company had sold to his cousin, Thomas Bancroft, before they made their exclusive agreement with the three manufacturers. This machine he remodeled so that he was able to use it for stitching shoes. At this time Mr. Nichols first heard of Elias Howe. Howe was just home from his unhappy European trip, and was laying claim to his patent rights. Mr. Nichols went to him in Cambridge and asked for permission to make use of his invention in stitching shoes.

Mr. Nichols joined interests with Howe and Bliss. Howe. with money provided by Bliss, succeeded in putting a line of sewing machines on the market. These machines were called the Howe improved machine. They were built on designs prepared by Mr. Nichols.

The profit on these machines enabled Howe to employ counsel and to fight his patent suits to a successful finish. Mr. Nichols continued in the machinery business as a partner in the firm of Nichols, Bliss & Co. and later of Nichols, Leavitt & Co.

When shoe manufacturers came in and saw the machines sewing shoes they decided that they must have them, and they bought. Mr. Nichols demonstrated the machine in several communities.

Old and New by Fred A. Gannon

*********************************************************

May 1853 DUBLIN EXHIBITION

Sewing Machine present at the Exhibition

Exhibition of Art and Art Industry

***

W. Spackman

The First introducer of the PATENT SEWING MACHINE in the United Kingdom

Four legs, needle & shuttle, two threads, lock stitch sewing machine

Three legs, two needles, two threads, double loop or double chain stitch sewing machine

************************1854************************

************************1855************************

William Frederick Thomas

GB 2.079 (September 14, 1855)

William Frederick Thomas of St. Martin's le Grand, in the City of London, for an invention for improvements in sewing machines.

Letters Patent sealed.

This invention has for its object several improvements in sewing machines.

The first is for stopping the movement of the work or fabric, when the needle thread is broken, and also when tho second thread is not correctly passed through the loop of the needle thread. For this purpose, a bent wire and instrument are applied in such manner that when the needle thread is properly drawn off its bobbin, the working of the machine goes on, and moves the fabric or work after each stitch; but when the thread is broken, or the second thread or instrument used to hold the loop on the other side of the fabric has not been passed correctly through the loop, then the wire and instrument move, and the apparatus for moving the fabric is not longer acted on. But if, at the next action of the needle, the second thread or instrument is correctly passed through the loop, the work goes on, the object of the improvement being, not to stop the machine, but only that part of it which moves the fabric or work after each passage of the needle through it.

The Second improvement consist of arranging sewing machines in such manner that the direction of the movement of the work or fabric may be changed by simply changing the foot or instrument, or by stopping the action of one of the instruments by which the work or fabric is moved, when the action of the machine is caused to be at right angles to the previous action, in consequence of the movement acting on the fabric or work being in a different direction to the previous one.

The Third improvement consist of arranging or combining the parts of a sewing machine in such manner that the fabric or work (or it might be the needle), in place of being moved continuously in one line, so that the stitches follow each other at a distance apart, the fabric is by the machine moved back a distance, and then forward, so as to obtain a description of back stitch.

The Fourth improvement consist of arranging or combining the parts of a sewing machine, in such manner that the fabric or work, in place of being moved constantly in one direction, so as to produce the stitches in a line, one after the other, the work or fabric is moved constantly in one direction, after each passage of the needle, but such motion is accompanied with a sideway motion, first in one direction and then in the other, by which the stitches follow each other, in inclined directions, and make a zig-zag line of work.

The Fifth improvement consist of making each stitch of sewing machines a fast stitch by causing the needle thread to be bent into a loop before it passes through the fabric or work, then to pass the point of the needle through such loop, in order to form a loop through the fabric, with its thread for the passage of the back or second thread, or the fastening may be by the second or back thread being formed into a loop, and passing the needle thread through such loop, and the second or back thread through the loop of the needle thread.

The Engineer (1856)

Joshua Kidd

GB 2.544 (November 12, 1855)

Joshua Kidd of 75, Newgate Street, London, an invention for improvements in machinery and apparatus for sewing or stitching and ornamenting cloth or other fabrics.

This invention received Provisional Protection, but notice to proceed with the application for Letters Patent was not given within the time prescribed by the Act.

***

...It was in the same year 1855 that one Joshua Kidd, of one of the Yorkshire towns, took out a patent for improvements in sewing machines which comprised at least one important novelty. It was the introduction of the disc tension, the passing of the upper thread between two discs, the pressure of the upper being regulated by a screw. Now these discs were of glass ; I saw one of them, which was brought to me at my then place of business in Cooper Street, Manchester. Had that patent been maintained, it would have controlled the Wilcox & Gibbs, who subsequently (viz., two years later) patented the identical thing, while the discs, so far as steel was concerned, were the subject of a patent taken out two years later still by the Grover & Baker Company. Poor Mr. Kidd never realised a penny for his invention, and has been unknown and unremembered for many years...

William Newton Wilson (Sep. 1892)

************************1856************************

************************1858************************

I. M. SINGER & CO.

R.E. SIMPSON & Co. (Agent)

Glasgow

************************1859************************

5 BRITISH MANUFACTURERS

*********************************************************

Below is a partial List of British Sewing Machine Manufacturers from 1852 to 1859, taken from Linda & Dave website, in chronological order.

(www.sewmuse.co.uk)

*********************************************************

Est. 1852 - 1887

Cleckheaton, Bradford, (Leeds) Yorkshire

Factory: Alma Foundry, Liversedge, Yorkshire.

Machine Made:

Singer No.2 1863

Circular Feed 1876-1882

Princess 1883

*********************************************************

Sewing Machine Agent (Grover, Baker & Co.)

*********************************************************

Est. 1854 - pre June 1867

Airedale works, Lawkholme lane, Keighley

Bradford (West Yorkshire)

Factory: Victoria Works, Keighley 1861 -1863

*********************************************************

*********************************************************

*********************************************************

Charles T. Judkins

Est. 1852 - 1863 +

*********************************************************

1852 - April 1855

Sugdens' & Bradbury Est 1852 - pre 1855

Factory: Primrose Bank, Oldham.

*********************************************************

Produced a range of sewing patent from 1853

W. F. Thomas & Co., sewing machine manufacrs

6 Buchanan Street (1856)

28 St. Enoch Square - new patent sewing machine (1857)

136 Buchanan Street - new patent sewing machine (1858)

GLASGOW

Thomas sewing machines were manufactured in Birmingham by

Charles & William Hardwood (liquidation in 1875)

The factory was then taken over by William Frederick Thomas & Co., who continued sewing machine making there until about 1884.

Machines Made: No.1 & No.2

***

since 1861 (to 1879)

54 Union Passage, Birmingham

*********************************************************

Sugdens', Bradbury & Firth dissolved 13th August 1855

*********************************************************

*********************************************************

W. N. Wilson & Co. Pre 1855 - August 1858

Newton Wilson & Co. Est 1858 - 1882 + (SM produced from 1864 on)

Machines Sold:

Lancashire May 1855 - Feb 1859

Boudoir December 1858 - 1866 supplied by Chas Howland

The Cottage 1858 - 1861

*********************************************************

Greenwood & Batley

Est 1856 - pre 1888

Factory: Albion Works, Armley Road

LEEDS (Yorkshire)

***

J. D. Abrams & Co. William Carver Est 1856 - 1879

Factory: Albert Works, Oldham

***

H. & W. Mitchell & Co. 1856 - 1858

***

Owen Robinson & Co. Est 1856 - 1885 +

***

William Pearson & Co. 1856 - 1875

***

Benjamin Kettle 1857 - 1862

***

T. & F. Sugden

1857

***

Thomas Bradford & Co.

Est 1857 - 1901 +

***

British Sewing Machine Co.

1858 - 1863

Factory: Britannia Works, 62 North Frederick Street

GLASGOW

***

Bradbury & Co.

by 1859 - 1874

Factory: 1866 Wellington Works

OLDHAM (Lancashire)

***

William Campion & Henry Johnson

1859 - Pre 1864

Factory: Hoyles' Factory, Woolpack Lane

NOTTINGHAM (Nottinghamshire)

***

European Sewing Machine Co.

c. 1859 - Nov 1862

*********************************************************

Hewett, Allott & Walker

Oct 1859 - May 1861

Partners:

John Hewett, Alfred Allott, Joel Eaton Walker partnership dissolved May 1861

SHEFFIELD (Yorkshire)

*********************************************************

William Jones

Est. 1859 - 1860

Jones factory was at Guide Bridge, Manchester. His first machine was made under licence in 1859

*********************************************************

Whight & Mann

Est. 1859 - 1878 Closed

Factory: Gipping Works, Station Road

IPSWICH ( Suffolk)

*********************************************************

Est. By Aug 1859 - Jan 1873

1870 Winter Wm. sewing machine manufacturer, Leeds

7 South Brook Street & 20, Swinegate

house 52 Springfield Place

LEEDS (Yorkshire)

Machines Made:

Howe Types 1, 2, 3 1861 - 1865

Singer Principle 1861 - 1863

*********************************************************

************************1862************************

1862 LONDON

INTERNATIONAL EXHIBITION OF INDUSTRY AND ART

The International of 1862, or Great London Exposition, was a world's fair. It was held from 1 May to 1 November 1862, beside the gardens of the Royal Horticultural Society, South Kensington, London, England, on a site that now houses museums including the Natural History Museum and the Science Museum .

************************1863************************

BRADFORD SEWING MACHINE MAKERS

in the 1863 Bradford Directory

************************1866************************

************************1884************************

THE SEWING MACHINE

The sewing machine has barely been invented thirty years, but it has already made itself a most formidable industry, in which a capital of ten millions sterling is employed, giving occupation to several hundred thousand workmen. The United States stand at the head of this industry. They employ more men, they have a larger capital, and turn out more machines than any other country in the world, and we may also say that their machines are generally better made and better finished than those made elsewhere. Consequently the majority of sewing machines to be found in this country are imported principally from the United States. Being an American invention, the Americans have made it a speciality of their own, and have also made it an industry of enormous importance. In this country the manufacture of sewing machines has never taken deep root. It has been, and is to the present day an industry of very secondary importance, and probably not half of the machines sold in Great Britain are of British manufacture.There are about ten makers of sewing machines in the United Kingdom, who turn out about 2,000 machines a week. In the United States there are forty factories of sewing machines, mostly of gigantic proportions, which turn out about 15,000 machines per week.This is not as it should be. Surely British manufacturers are not so flourishing that an important branch of industry should be left to such an extent in the hands of foreigners. Everywhere we find the doors of foreign countries closed against our goods. Every day foreigners learn more and more to do without us, and to supply themselves with goods with which we have hitherto supplied them. It appears to us, therefore, monstrous that we allow the sewing machine trade to be monopolised, even as far as the supply to our own people is concerned, by Americans and Germans. For the latter are also making great strides with the manufacture of their sewing machines. Their machines are cheaper than those of the Americans, though not so well finished. But for the purposes of the clothiers and other manufacturers they do quite well, and whilst the family machine will be generally one of American manufacture, those to be found in workshops will generally be British and German. It must be admitted that the position of the British manufacturer is a difficult and a disheartening one. Whilst the wages exacted by the workman are very much higher than those in any other country. Great Britain is the receiving shop of every nation's surplus productions, and whilst every country in Europe and America barricades its gates with enormous duties against British goods, Great Britain receives placidly all what other nations choose to send here. Our ruling classes allege in extenuation of this monstrous policy, that the British workman is so highly paid because he can do more and better work than foreign workmen, an assertion which may have been true at one time, but is most assuredly not true any longer. We hear also from our so-called statesman, that the national interests demand that the consumer or buyer should have the best goods at the lowest price, no matter where produced. Lastly, a new maxim, "the survival of the fittest" has been started, which means that the producer is to give way to the consumer, and that if, in spite of all obstacles which a conglomeration of circumstances has put in the way of the British manufacturer, he can no longer compete with the foreigner, well, he must go to the wall, a heresy which would have shocked our statesmen one hundred years ago. Evidently enlightenment does not come with age. However, it is not our purpose to run our heads against a stone wall. It is of no use waiting and speaking agahist one-sided free trade, for public opinion is still against us. But we put forward these sentiments as strong reasons for all Manufacturers to pay attention to the details of their business, and to fashion their goods according to modern requirements, and look out for every improvement. It will be our business to record everything which can be of use to the manufacturers, to note all improvements made in sewing machines and other domestic machines, and to report the state of trade abroad. The sewing machine is no longer what it was when first introduced. Instead of a rattling, noisy machine, only fit for hemming and sewing , we have now a machine of elegant design and useful for a multitude of purposes, and as the same will be further improved and its purpose still more extended, there will be many more machines bought. We trust our manufacturers will be fully alive to this, and try not to be beaten by America as to design and finish, nor by Germany as to price. We hope we shall be able to do some good to British manufacturers and to the public generally.

Sewing Machine Gazette April 1884