- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

CHRONOLOGICAL HISTORY OF BRITISH SEWING MACHINES PATENTS

PART 1

from 1755 to 1851

************************1755************************

Charles Frederick Weisenthal

GB 701 (June 24, 1755)

A grant unto Charles Frederick Weisenthal, of the city of London, merchant, of his new invented art of working fine thread in needlework after the manner of Dresden needlework; to hold to him, his exec ,admrs & assigns, within England, Wales, & town of Berwick-upon-Tweed for the term of 14 years pursuant to the statute ; with a clause to enroll within 3 calendar months from the date hereof.

************************1770************************

Robert Alsop

GB 955 (March 22, 1770)

A grant unto Robert Alsop, esqre, of his invention of a new species of embroidery for cloathes (to be manufactured in gold or silver on silk ribband and woollen, linnen, cotton, or mohair,) to match any colour, which he calls loom embroidery ; to hold to him, his exors, admors, and assigns, within England, Wales, and town of Berwick-upon-Tweed, and also in the colonies and plantations abroad, for the term of fourteen years pursuant to the statute ; with a clause to inroll the same within four calendar months from the date hereof.

************************1790************************

Thomas Saint

GB 1.764 (July 17, 1790)

A grant unto Thomas Saint, of Greenhill's Rents in the parish of Saint Sepulchre and county of Middlesex, cabinet maker, of his new invented method of making and completing shoes,

boots, spatterdashes, clogs, and other articles by means of tools or machines also invented by him for that purpose ; to hold to him, his exors, admors, & asss, within

England, Wales, & town of Berwick-upon-Tweed, and also within His Majesty's colonies and plantations abroad, for the term of 14 years pursuant to the statute ; with

a clause to enroll the same within two calendar months from the date hereof.

************************1804************************

John Duncan

GB 2.769 (May 30, 1804)

A grant unto John Duncan, manufacturer in Glasgow, for his 30th May 1804. improved method or means of tambouring or raising of flowers, figures, or other ornaments upon muslins, lawns, and other cottons, cloths, or stuffs, or upon silk, linen, or woollen cloths or stuffs, or upon cloths or stuffs composed partly of silk, flax, cotton, or woollen ; to hold to him, his exors, admors, and assigns, within England and Wales and the town of Berwick-upon-Tweed for the term of fourteen years pursuant to the statute ; with a clause to enroll the same within one calendar month from the date thereof.

In 1804, a sewing machine was built by the Englishmen Thomas Stone and James Henderson.

Thomas Stone and James Henderson got French patent for their machine.

************************1807************************

James Winter

GB 3.012 (February 20, 1807)

A grant unto James Winter, of Stoke under Hamdon, in the county of Somerset, glove manufacturer, for his invented machine for sewing and pointing leather

gloves with neatness and strength, much superior to that which is effected by manual labour ; to hold to him, his exors, admors and assigns, within that part of our united kingdom

of Great Britain and Ireland called England, our dominion of Wales and town of Berwick upon Tweed for the term of fourteen years pursuant to the statute ; with a clause to inroll

the same within one calendar month from the date thereof.

William Chapman & Edward Walton Chapman

GB 3.078 (October 30, 1807)

A grant unto William Chapman, of the town and county of Newcastle upon Tyne, civil engineer and Edward Walton Chapman, of the same place, rope maker, for their invented method or methods of making a belt or flat band, for the purpose of drawing coals and other minerals up the pits or shafts of mines, and for raising of heavy articles in any situation whatever; to hold to them, their exors, admors and assigns, within that part of our united kingdom of Great Britain and Ireland called England, our dominion of Wales, and town of Berwick-upon-Tweed for the term of fourteen years pursuant to the statute; with a clause to inroll the same within one calendar month from the date thereof.

************************1821************************

James Winter

GB 4.627 (December 19, 1821)

A grant unto James Winter, of Stoke under Hamdon, in the county of Somerset, gentleman, for his invention for certain improvements in a machine for sewing and pointing leather gloves with neatness much superior to that which is effected by manual labour ; 2 months.

************************1829************************

Henry Bock

GB 5.788 (May 2, 1829)

In May, 1829, a patent was granted, in England, to Henry Bock, for a tambouring machine, the needle having two points and an eye ; but tambouring is not sewing.

************************1841************************

Edward Newton & Thomas Archbold

GB 8.948 (May 4, 1841)

In England, Edward Newton and Thomas Archbold invented and patented a machine on May 4, 1841, for tambouring or ornamenting the backs of gloves.

Their machine used a hook on the upper surface to catch the loop of thread, but an eye-pointed needle from underneath was used to carry the thread up through the fabric. The machine was designed to use three needles for three rows of chain stitching, if required. Although the machine was capable of stitching two fabrics together, it was never contemplated as a sewing machine in the present use of the term. Their British patent 8.948 stated it was for improvements in producing ornamental or tambour work in the manufacture of gloves.

Edward Newton, of Leicester, manufacturer and Thomas Archbold, of the same place, machinist, for improvements in producing ornamental or tambour work, in the manufacture of gloves.—Sealed 4th May—6 months for enrollment.

************************1844************************

Leonard Bostwick

GB 10.134 (April 2, 1844)

The first machine adapted in this country to the sewing of two pieces of cloth together, without the aid of hand labour, was one patented on the 2nd of April, 1844, by Leonard Bostwick, the invention having been communicated to him by a foreigner.

This machine produces a running or basting stitch. Fig. 9 represents a side elevation of the working portion of the machine, with one of the side plates removed, in order, to show the internal arrangement. The cloth enters between the large toothed wheel, A and the smaller wheel, B and by that means is formed into doubles or crimps, as shown by the waving or undulating line.

The needle, C, shown in detail in fig. 10, is held stationary by the additional pinions, n and E and wheel, F. It is made in the peculiar form shown, in order that it may be passed over the small pinion, D and be thereby always kept up to its work, and prevented from running out of the machine. The pinion, D, is actuated by causing the spur wheel, G, on the axle of the wheel, B, to gear into, and drive a pinion mounted on the axle of the pinion, n, outside the casing. A groove is made in the several wheels and pinions, A, B, D, E, and F, for the purpose of receiving the needle, and holding it steady, and in its proper position. The needle is always stationary, and has an eye formed at one end, as in ordinary needles, for the purpose of holding the thread, which may either be loose or run off continuously, from a ball or reel, as the operation of sewing proceeds. The length of stitch will, of course, depend on the pitch of the doubling or crimping teeth in the several wheels and pinions. H is the pinion which drives the large wheel, A. A machine constructed on the principle of this patent has been largely introduced into this country, for the use of bleachers, printers, dyers, finishers, and lace manufacturers and for the mere purpose of tacking two pieces of material together for temporary purposes, it is of considerable value.

US 2.982 (March 4, 1843)

John Fisher & James Gibbons

GB 10.424 (December 7, 1844)

A patent was granted to John Fisher and James Gibbons, of Rudford, Nottinghamshire, for certain improvements in the manufacture of figured or ornamented lace, or net, and other fabrics, bearing date the 7th of December, 1844. Amongst other things described in the specification of this invention is a machine for sewing cords, threads, gimp, yarn or fabric in pattern, on to fabrics. This, according to the specification, is effected by the aid of a needle and shuttle and in justice to Messrs. Fisher and Gibbons, we feel bound to state that it is to them we are indebted for the suggestion of, combining a needle with a shuttle, for the purpose, of uniting two fabrics, by means of two threads locked together, so as to produce a lasting stitch. This machine contained several sets of needles and shuttles, working simultaneously, and was intended more for the purposes of ornamentation than as a bona fide sewing machine. We cannot learn that it has ever been put into practice.

Fig. 11 represents a sectional elevation, and edge view, of the needle specified by Messrs. Fisher and Gibbons. This needle is bent, or curved, in the form of a bow, and is made with two eyes, the one being near the point, and the other at the bottom of the bend. The curved portion of the needle, between these two eyes, is grooved, in order that the thread may lie therein without rubbing against the cloth during the passage of the needle. The object of the bend is to keep the loop of the thread open when passed through the cloth, so as to enable the shuttle to traverse freely with its second thread through the needle loop.

The shuttle is shown in longitudinal section at fig. 12 and is fitted with a spool or bobbin containing the second thread. A notch, or recess, a, is made at each end of the shuttle, for the purpose of imparting motion thereto, as we shall fully explain further on.

Fig. 13 shows the shuttle, A, in the act of passing through the loop of the needle, B, above the cloth, whereby the needle thread is locked, or prevented from being- drawn out by the descent of the needle. The needles are secured to a needle bar placed beneath the fabric, and in order to pass the curved portion, or bow through the fabric, a “ shagging “ motion is imparted to the needle bar, simultaneously with its rising and falling motion.

Fig. 14 represents a transverse section of apportion of the machine, showing the mode of actuating the shuttle. A, is the shuttle and B one of the needles, which is cast in a "lead" secured to the needle bar, c. The shuttle, which is pointed at both ends, is moved to and fro so as to pass through every fresh loop formed by the needle, by means of the two vibrating arms, D, D’ . These arms are carried by overhead rocking shafts worked by cams. The vibrating ends of the arms, n, d’, are slotted, so as to receive necks or studs on the bars, E, E’, which rest on the fixed platforms, F, F’ and are slided to and fro by the swinging of the arms, D, n’. On the ends of the bars, E, E’ , are projections which form bearings for the axes of the catch bars, G, G’. To the ends of each catch bar is fixed a finger, H, H’, moving along the guide rails, I, I’ ; hence, as the arms, swing together, the one finger will be moving up, whilst the other is moving down the inclined planes, K, K’, thus causing the catch bars, G, G’ to rook slightly in their bearings. Each of these bars carries as many catches. L, L’, as there are shuttles in the machine and the bent ends of the catches are made to enter or withdraw from the notches, a, a, in the ends of the shuttles, by the turning of the catch bars. When either of the fingers is on the lower portion of its guide rail, that is, in the position shown by the finger, H’, then the corresponding catches, L’, will be down, or engaged in the notch of the shuttle, which is thus for a time connected to the sliding bar, E’, and will consequently move with it at the next vibration of the arm, D’. As the finger, H’, slides up the incline, K’, the catches, L’ , will be gradually elevated out of the shuttle, whilst the opposite catches, L, will begin to come into action by the descent of the finger, H and having engaged themselves with the shuttles, the backward motion of the sliding bar, E, will draw them all through the needle loops. The needles then descend, and the shuttle threads will be fastened down by the threads of the needles. The fabric, M, is now traversed to the proper position for the next stitch, and the needles again rise up through the fabric, and form another set of loops, through which the shuttles are passed back again, in the manner above described and so on, until each pattern is completed. The fabric is carried by a pair of cloth rollers, capable of sliding horizontally in two directions, namely, laterally and longitudinally; these combined movements being sufficient to produce any required design N, N, are two bars, over which the fabric passes, and is kept stretched during the process of ornamentation. A rod or bar, o, running from end to end of the machine, carries two other bars, P, P, which are hinged thereto, so that they may be turned up when it is desired to look below. These hinged bars carry combs or plates, Q, Q, which form shuttle races for the shuttles, one for each shuttle and the combs or plates carry wires, R, which support the shuttles in their movements across from one set of catches to the other. The slack of the threads of the needles is prevented by weighting the thread roller or beam. The ornamenting produced by the shuttles will of course depend on the nature of the cord, yarn or gimp used, which will be sewn down in pattern by the movement of the fabric each time the needles go down. When a second fabric is fastened by the threads of the needles, the shuttle threads may be of the ordinary kind used in sewing.

Fisher & Gibbons invented a sewing machine without knowing it.

it was sufficient to invalidate Howe's (or Thomas's) patent, parts of which were accordingly disclaimed.

************************1845************************

A subsequent patent was granted on the 10th of June, 1845, to John Fisher, James Gibbons, and Thomas Roe, (GB 10.716) for some modifications of Fisher and Gibbon's patent above referred to. These modifications, however, contained little or nothing in common with the present sewing machines, and need not therefore be further commented upon.

************************1846************************

Arthur Eldred Walker

GB 11.025 (January 6. 1846)

Arthur Eldred Walker obtained a patent on the 6th of January, 1846, for improvements in machinery for sewing.

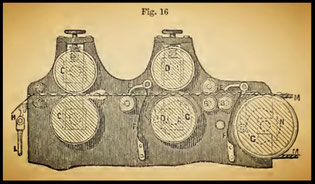

The stitch produced by Walker’s machine is a running or basting stitch, precisely similar to that of Bostwick, above alluded to; but in place of using toothed wheels for the purpose of doubling or crimping the cloth, Walker employs a rising and falling bar, which alternately carries the fabric above and below the point of the needle. Fig. 15 of our illustrations shows two views of the needle employed by Walker and Fig. 16 represents a longitudinal vertical section of the essential parts of Walker’s sewing machine. The needle, A, is perfectly straight and is formed with two projections or stops, a, a, the object of which we shall presently point out. When fitted into the machine, the needle remains stationary and is supported in grooves in the small rollers, B, B, such rollers turning freely in their bearings as the fabrics are moved along the needle by the larger grooved rollers, C, C, and D, D, as we shall afterwards explain.

The stops or projections on the needle from moving back as the fabric is pushed on to it. These catches have a tendency at all times, by the action of their springs, F, F1, to hear against the needle; but they are respectively held up at proper intervals by the cam surfaces, o, G1, so as to allow the fabrics, as they have been sewn and have accumulated on the needle, to pass under the catches. H is the rising and falling bar, which alternately presents the fabrics above and below the point of the needle. This bar is cranked or bent at each end and works on centres at K, on each side of the machine. The requisite rising and falling motion of this bar is derived from a crank and connecting rod, L, a portion of the latter only being shown in our illustration. In order to keep the edges of the fabric in proper position, a guide plate is fitted to the bar, H, having a horizontal slit made therein, through which the fabrics to be united are passed. The front large rollers, C, C, are kept in constant contact, so as to draw the work forward along the needle as fast as it is presented to the needle point. The second pair of rollers, n, D, are not always in contact ; but are brought together at regular intervals, when the catch, e, is elevated, in order that the fabrics accumulated on the needle may be moved along. When the catch, E, is again depressed, the catch, E1 is elevated in a similar manner, and the accumulated fabric is drawn, under it by the action of two endless cords, M, passed round each end of the roller, N, and kept in a proper state of tension by passing round another roller not shown in the cut, which latter or tension roller is held back so as to give the desired tension to the cords by a weight and pulley. In these endless cords is fitted a board, which carries the bobbin of thread used in sewing the fabrics together. The fabrics are, in the first place, sewed together for a short distance by hand before being introduced into the machine, and the sewed ends of the fabrics are then attached to the board on the endless cords, which, receiving an intermittent motion from the machine, will draw along the fabrics as fast as they are sewed together, the bobbin carried by the board giving out its thread as the sewing proceeds.

Up to the latter end of the year 1846, there had been no machine in use in this country which would satisfactory accomplish the operation of sewing; the machines previously employed or known, being for the most part intended for purely ornamental work or embroidery, with the exceptions of Bostwick's and Walker's machines.

*********************************************************

Elias, Jr. Howe US 4.750 (Sept. 10, 1846)

After patenting his invention, Howe spent three discouraging years in both the United States and in England trying to interest manufacturers in building his sewing machine, under license. Finally, for £250 sterling, he sold the British patent rights to William Thomas and further agreed to adapt the machine to Thomas manufacture of umbrellas and corsets.

Mr. Thomas, some time later, paid £2.000 to a person who made some improvement in the feeding apparatus

It is interesting to note that when William Thomas applied for the British patent of the Howe machine (issued Dec. 1, 1846), the courts would not allow the claim for the combination of the eye-pointed needle and shuttle to form a stitch, due to the Fisher and Gibbons patent of 1844.

read more

************************1848************************

Jean Marie Magnin

GB 12.060 (February 9, 1848)

hooked needle, one thread,

chain stitch sewing machine

In 1848 Thimonnier Barthelemy received a British patent with his associate Jean Marie Magnin. He had improved his machine, making it of metal instead of wood, and through the assistance of M. Magnin, of Villefranche, he secured a patent in England, which was finally sold to a Manchester company.

from Needlebar:

| Lakeman & Company | Manchester |

1848

|

Cousobrodeur (Thimmonier) |

Thimonnier's machine used a hooked needle; the thread was below the cloth, and the hook of the needle being thrust through the fabric caught the thread, and brought to the upper side a loop. Retaining this loop, the needle passed through the cloth again for another loop, and the second loop was drawn through the fabric and the first loop, thus making a chain stitch. It is stated that this machine would sew two hundred stitches per minute and, if the poor tailor of St. Etienne had not been strangely unfortunate, he would have gained the reward he merited for his clever invention.

William Thomas

GB 12.221 (July 26, 1848)

bent needle & hook, one thread,

chain stitch sewing machine

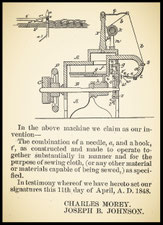

Charles Morey

&

Joseph B. Johnson

US 6.099 (February 6, 1849)

needle and hook, one thread,

chain stitch sewing machine

Although the patent was not granted until February 6, 1849, the application had been filed in April 1848.

************************1849************************

Robert Brown

GB 12.462 (February 8, 1849)

A grant unto Robert Brown, of Sadler's Wells, in the county of Middlesex, engineer, for his invention of improvements in machinery for perforating, sewing, stitching, pegging and

riveting; 6 months.

*********************************************************

William Thomas

GB 12.736 (August 9, 1849)

A grant unto William Thomas, of Cheapside, in the city of London, merchant, and John Marsh, foreman to the said William Thomas, for improvements in the manufacture of looped fabrics, stays, and other parts of dress; also an apparatus for measuring; being partly a communication; 6 months.

*********************************************************

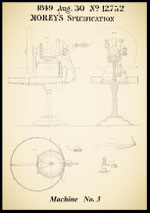

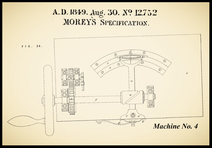

Charles Morey

GB 12.752 (August 30, 1849)

5 Machines' improvements

**********************AUGUST**************************

curved needle & curved shuttle, rotary machine (No. 3)

curved needle & shuttle, reciprocating curvilinear motion, (No.4)

vibrating shuttle machine

**********************OCTOBER*************************

*********************NOVEMBER************************

Wilson, a native of Willett, New York, was a young cabinetmaker at Adrian, Michigan, in 1847 when he first conceived of a machine that would sew. He was apparently unaware of parallel efforts by inventors in distant New England. After an illness, he moved to Pittsfield, Massachusetts, and pursued his idea in earnest. By November 1848 he had produced the basic drawings for a machine that would make a lockstitch.The needle, piercing the cloth, left a loop of thread below the seam. A shuttle carrying a second thread passed through the loop, and as the tension was adjusted a completed lockstitch was formed. Wilson’s shuttle was pointed on both ends to form a stitch on both its forward and backward motion, a decided improvement over the shuttles of Hunt and Howe, which formed stitches in only one direction. After each stitch the cloth was advanced for the next stitch by a sliding bar against which the cloth was held by a stationary presser. While the needle was still in the cloth and holding it, the sliding bar returned for a fresh grip on the cloth.

Wilson made a second machine, on the same principle, and applied for a patent. He was approached by the owners of the Bradshaw 1848 patent, who claimed control of the double-pointed shuttle. Although this claim was without justification, as can be seen by examining the Bradshaw patent specifications, Wilson did not have sufficient funds to fight the claim. In order to avoid a suit, he relinquished to A. P. Kline and Edward Lee, a one-half interest in his U.S. patent 7,776 which was issued on November 12, 1850.

Grace Rogers Cooper

************************1850************************

John Alexander Lerow

GB 13.321 (November 7, 1850)

Registration of the Blodgett & Lerow's (American) patent for sewing machine.

A grant unto John Alexander Lerow, of Boston, in the United States of America, gentleman, for his invention of certain improvements in sewing machines; 6 months.

*********************************************************

David Christie

GB 13.325 (November 7, 1850)

A grant unto David Christie, of Saint John's Place, Broughton, in the borough of Salford and county of Lancaster, merchant, for improvements in machinery or apparatus for preparing, carding, spinning, doubling, twisting, weaving and knitting cotton, wool and other fibrous substances; also for sewing and packing; 6 months ; a communication.

************************1851************************

Frederick R. Robinson

GB 13.494 (February 7, 1851)

A grant unto Frederick R. Robinson, of Boston, in the state of Massachusetts, of the United States of North America, for his invention of a new and useful sewing machine; 6 months ; colonies.

*********************************************************

The sewing machine was first introduced into these countries in 1846, when a patent was obtained for the invention, which we derive from the other side of the Atlantic ; but this first attempt was found to be too complicated for ordinary use. Several modifications were subsequently made, until in 1851 the Lancashire Sewing Machine Company was formed and short as is the time since the first patent was taken out.

W. & C. Mather

of Salford Iron Work Manufacturer. Manchester

*********************************************************

Bacon, S. F.

of Boston, Massachusetts, sewing machine

*********************************************************

Sherburne C. Blodget and John Alexander Lerow

of USA, sewing machine. (awarded)

*********************************************************

Charles Barlow

89 Chancery Lane, Imp.. Patent sewing machine, with two threads.

*********************************************************

Judkins, Charles Tiot

Sewing machine, capable of sewing 500 stitches per minute. Patent self-acting machine, for closing metals upon the eyes or loops of healds. (prototype of sewing machine made by Platt Brosof Oldham)

needle & shuttle, two threads, lock stitch sewing machine

*********************************************************

Jean Marie Magnin

Inventor, Villefranche (Rhône)

Sewing, embroidering, and cord making machine, called Cousobrodeur. New invention, patented in England. Samples of sewing on different stuffs.

barbed or hooked needle, one thread, chain stitch sewing machine

*********************************************************

At the Exhibition at London in 1851, on account of inexplicable bad luck, Thimonnier's machine was not ready for the examination of the commissioners; whereas the Americans exhibited their first improvements to Thimonnier's machine and the shuttle and two-thread machine of Elias Howe.

The Manufacturer and Builder (1888)

William Thomas did not exhibit the productions of Elias Howe whilst employed in his English factory.

William Newton Wilson (Jan. 1892)