- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

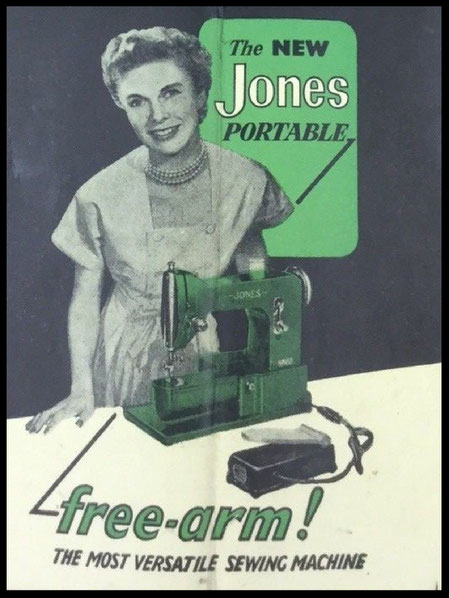

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

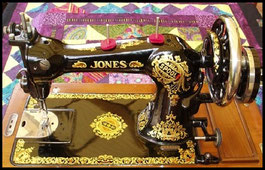

JONES CB MACHINES

PREFACE

The Singer Model 15, "Improved Family" (Oscillating Shuttle) was produced between 1879 and the early 1890's. Frister & Rossmann started produce their Oscillating Shuttle machine around 1900.

According to my database, Jones CB machines seam to come into production the same year the company ended the production of Spool machines. The early Jones CB have the same decals used for Jones Family CS machines , for Jones Medium CS and Jones Spool machines. This style of machines were possibly manufactured between 1930 and 1941 c..

TYPE 11

from 1930 c.

*********************************************************

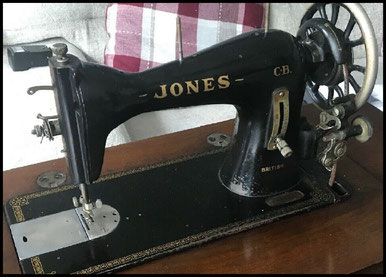

The below machines were made after the WWII

This new Jones Central Bobbin machines have the same flat bed decal. Decal similar to the Jones Family CS machines .

This kind of decal was used until 1958 c.

"BRITISH"

FACTORY GUIDE BRIDGE MANCHESTER

The below Jones CB "BRITISH" treadle machines, have a decorated front face plate and the old style stitch length regulator but lost the old fashioned decals. The serial number appear to be a continuation of the old system.

The above Jones CB "BRITISH" treadle machine has a black front face plate. The serial number on top right hand side of the bed. Change in the pillar slot shape for the stitch length regulator.

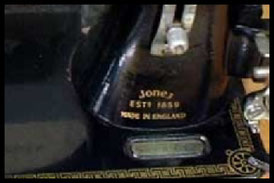

"JONES EST. 1859 MADE IN ENGLAND"

The below "JONES EST. 1859 MADE IN ENGLAND" machine has the serial number probably located underneath. It has an old style pillar slot shape for stitch length regulator

*********************************************************

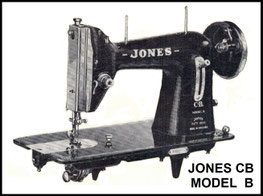

JONES CB MODEL B

For domestic use or all classes of light manufacturing

The Jones Model B Central Bobbin sewing machine is ideal for steady, continuous work. It combines robustness with grace of line. The semi-rotary action gives smooth, swift, silent running; the simplicity of the well-balanced mechanism, the precision workmanship and sound design, ensure trouble-free sewing hour after hour, year after year ... the Jones is yours for a lifetime.

FEATURES of the JONES MODEL B CENTRAL BOBBIN

Semi-Rotary Central Bobbin with Easily Detachable Shuttle Race

Link Take-Up

Drop Feed for Darning & Embroidery

Thread Cutter

Graduated Stitch Regulator Plate

Sews Backwards and Forwards

Easy Flow Presser Foot

Automatic Bobbin Winder and Tension Release

Solid Balance Wheel

Finished in Black or Colour

Bright Parts Chromium Plated

*********************************************************

1955 c.

The Singer 15-91 is the final model in a class beginning in the late 1890's with the 15-30 class, which was replaced in the mid-1930's with the Singer 15-88 treadle operated and 15-89 hand cranked, followed by the 15-90 w/side motor and belt, then the 15-91 w/built-in "potted" motor.

The last Singer 15-91 made by "The Singer Manufacturing Company" was in the mid 1950's.

The Singer 15-91 in the photo on the left was built in 1953, according to the Singer machine serial numbers lookup (for double letter prefixes). It was fully functional, with a rebuilt "potted" motor.

This Singer 15-91 is capable of sewing cloth and Denim fabrics to over 5/16" thick with the standard foot. This includes materials like Sunbrella. Sewing sticky materials, like Marine Vinyl and soft leather, requires an even-feed-walking foot, or a roller foot attachment (low shank). The standard steel presser foot, when sufficiently tensioned down to prevent the material from lifting with the needle, usually drags the top layer of sticky material out of alignment with the other layers. An even-feed or roller foot compensates for this and allows the top layer to move freely, while still maintaining sufficient top pressure as the needle moves up. It also reduces the maximum clearance under the foot by about 1/16 inch.

The Singer 15-91 uses standard household series HAx1, which is available wherever home sewing needles are sold. Note, that on a Singer 15-91, the needle's flat side and eye faces left and it threads from right to left. The maximum needle size available is #125/20, which is good for sewing through thick material. The largest thread size it can properly sew and tension is #92 bonded nylon, but it is best limited to #69 nylon. Too much thread tension will overstress the take-up parts and the motor.

*********************************************************

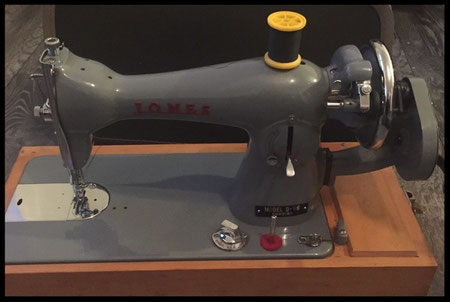

The below machines were possibly made after 1960

*********************************************************

MODEL D

*********************************************************

MORE D.66 MACHINES

*********************************************************

*********************************************************

*********************************************************

*********************************************************