- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

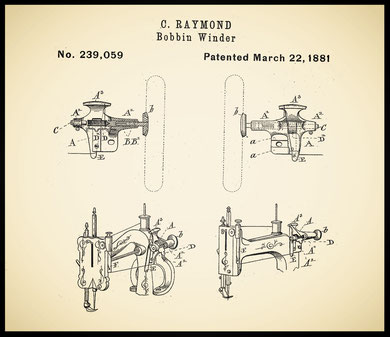

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

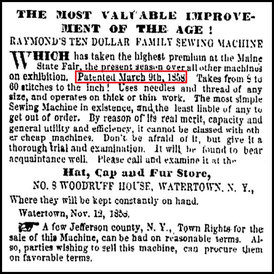

RAYMOND'S SEWING MACHINES

*********************************************************

April 14, 1857

NETTLETON & RAYMOND

Two-Threads Chain-Stitch Sewing Machine

One of the most ornate of the early, small, hand-turned sewing machines was patented and manufactured by Willford H. Nettleton and Charles Raymond whose first patent US 17.049 was received on April 14, 1857. The patent model, believed to be a commercial machine, is beautifully silver-plated. Whether this was a special one-of-a-kind model, or whether the inventors tried to make a commercial success of a silver-plated machine is not known. The machine made a two-threads chainstitch, taking both threads from commercial spools.

In 1850 Census, Glenn's Falls' population was of 2.717 inhabitants.

Glenn's Falls is 150 miles away from Bristol.

Not sewing machines manufacturers in Glenn's Falls.

In 1858 Henry E. Fickett was presidents of the Glenn's Falls village.

Willford H. Nettleton was a manufacturer of clock parts. He was also one of major stockholder in the Pequabuck Oil Company and was one of the oldest and best-known residents of Bristol. He was reside at 123 Maple Street and from around 1860 at 115 Maple Street.

*********************************************************

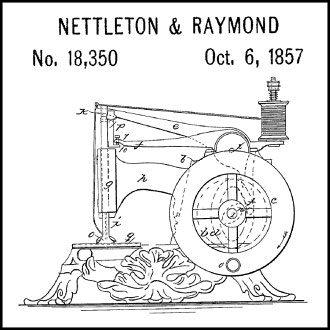

October 7, 1857

NETTLETON & RAYMOND

One-Thread Chain-Stitch Sewing Machine

In October 7, 1857, Willford H. Nettleton and Charles Raymond had received their second patent US 18.350. This time the one-thread chainstitch machine was brass and gilt-brighter, but less expensive.

*********************************************************

March 9, 1858

NETTLETON & RAYMOND

Sewing Machine

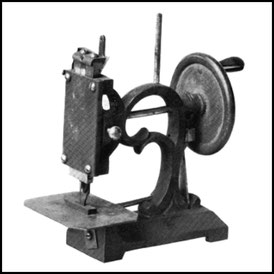

The small, hand-turned, sewing machines some of which were called Common Sense, were manufactured by at least three companies and possibly more.

The earliest ones were those made by Nettleton & Raymond based on Charles Raymond's patent US 19.612 of March 9, 1858, which featured a hinged presser foot acting as the top feed.

*********************************************************

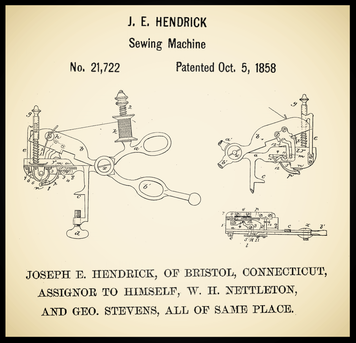

October 5, 1858

Willford H. Nettleton and Charles Raymond began manufacturing sewing shears’ handles machines under the patent of J. E. Hendricks.

*********************************************************

November 30, 1858

In November 30, 1858 patent US 22.220, improvement of the two-thread chainstitch machine, was in the name of Raymond, assignor to Nettleton, although the machines of this type bear neither name nor patent date.

By this time, Nettleton and Raymond had moved from Bristol, Connecticut, to Brattleboro, Vermont. In Brattleboro at this time Thomas H. White and Samuel Barker were manufacturing a small machine called the Brattleboro.

The patented improvement of the two-thread chainstitch machine received that year was in the name of “Raymond, assignor to Nettleton”, although the machines of this type bear neither name nor patent date. No record of the price for which they were sold has been found, but it would be fair to estimate that it was probably about $25. This style of machine was discontinued when the manufacture of the simpler, more profitable New England model began, a machine that Raymond had initiated just before the partners left Bristol.

NETTLETON & RAYMOND

Double Lock-Stitch Family Machine

*********************************************************

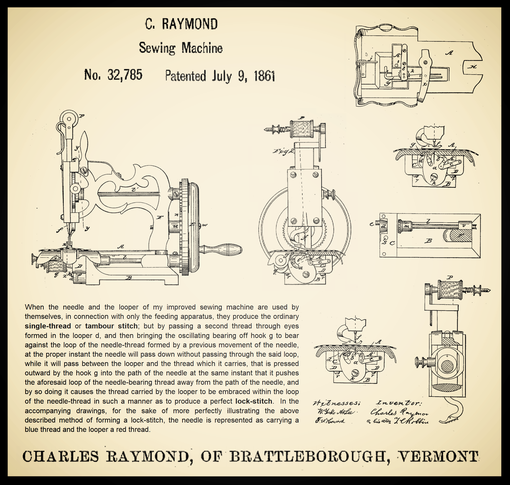

July 9, 1861

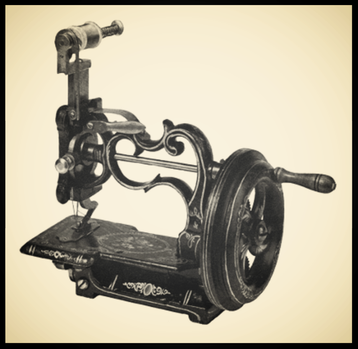

The Raymond lock-stitch sewing machine

with a "walking pressure foot"

*********************************************************

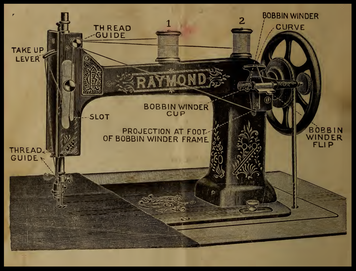

1861 - 1886 c.

The Raymond lock-stitch sewing machine

with a "walking pressure foot"

The Raymond chain-stitch sewing machine

with a "walking pressure foot"

On July 30, 1861, Raymond received a patent for an improved looper; this date is found on all machines later manufactured by the inventor.

Half-motion loopers are very largely used in private families in Europe. Those made on the pattern of Charles Raymond, of Guelph, Ontario, are the most popular. It is a very reliable article. A missed stitch seldom occurs and when it does the operator who habitually uses it can tell it by the appearance on top. The loop from the needle does not require to be so low as when a shuttle is used. If the looper point will catch it that is enough. The thread should fill the needle's eye more than if it were for the shuttle indeed, for sewing laces or thin lawns. The thread should fill the reel groove, because if the fabric does not make some friction on the thread, there will be no loop to be caught. In half-motion " loopers " the looper should be so placed that the needle will enter the centre of it. Soft finished thread will do (and is best for wear), but is more likely to make a miss than glazed thread.

extract from The Sewing Machine Gazette 1886

White left Vermont in 1862 and went to Massachusetts. There, in partnership with William Grout, began to manufacture New England machines; these were basically the same as the Raymond machines. After a short time, Grout left the partnership with White and moved to Winchendon, there continuing to make New England machines for approximately one more year.

In 1865, J. G. Folsom of Winchendon exhibited a New England machine at the Tenth Exhibition of the Massachusetts Charitable Mechanics Association along with his Globe machine. Whether both machines were manufactured by him or whether he might have been exhibiting one of Grout‘s machines is not known.

There is a great similarity between these machines and the Improved Common Sense sewing machines of the 1870s. It is believed that the name Common Sense was given by frugal New Englanders to several of the cheaper chainstitch machines of the 1860s

*********************************************************

It bears a patent date of 30 July 1861 on the throat plate and this refers to Raymond's last American patent for an improved looper. This machine was manufactured with two objectives in mind . Most early sewing machines were combination machines (meaning they could sew on both coarse or fine material), but they generally required a skillful workman to put them in order for the weight of the material to be sewn . The aims of the Raymond machine were to be so simple that anyone could change it to accommodate almost any weight of fabric and at the same time make it at so small a cost as to be within the means of everybody . This machine sold for twelve dollars and was probably the cheapest one on the market throughout the 1860s . A single-thread machine has one major drawback . The chain-stitch is not always a sufficiently secure stitch for domestic sewing as it unravells easily and for this reason the lockstitch machine is more desirable.

*********************************************************

1872

On 18 April 1872 Charles Raymond took out his first Canadian patent for an improved lockstitch sewing machine called the Raymond Household Sewing Machine . This is the earliest Raymond machine known to exhibit a beaver, which became the Raymond trademark.

*********************************************************

*********************************************************

sources:

The Invention of the Sewing Machine

by Grace Rogers Cooper

***

A STITCH IN TIME :

THE SEWING MACHINE INDUSTRY OF ONTARIO, 1860 - 1897

by Martha Eckmann Brent

***

***

Bristol Historic Homes

By Lynda J. Russell

***