- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

Room 18

by

Scientific American

1896

THE SEWING MACHINE

Fifty years have passed since Elias Howe applied at Washington for a patent on his sewing machine and placed on fle the working model which is herewith illustrated. On the 10th of September, 1846, the patent was granted. That day may justly be written down as the birthday of the sewing machine, the practical modern machine as we know it to-day-and the year 1896 is therefore the semi-centennial anniversary of one of the greatest labor-saving devices of modern times.

In according to Elias Howe the title of father of the sewing machine, one is not unmindful of the earlier attempts of other inventors, whose devices, more or less crude and impractical, contained a suggestion of the future combination of parts, which was to make possible mechanical sewing. The records of the English Patent Office show that on July 17, 1790, Thomas Saint patented a sewing machine, which had a horizontal cloth plate, a vertical reciprocating needle, a continuous thread fed from a spool, an automatic feed and means for tightening the thread. It sewed with a chain stitch, an awl forming the hole and a needle with a notch in its lower end pushing the thread through the cloth and forming the loop. Thimonnier, in 1830, patented a machine in France, in which a barbed needle, shaped like a crochet needle, was carried through the material from above and caught a thread which was on the lower side, bringing it up through the cloth and forming a chain stitch on the upper side.

Walter Hunt, of New York, applied for a patent in 1854 and showed that in 1834 he had made and sold sewing machines which embodied an eye-pointed needle and a shuttle. Whatever success Hunt may have had with these designs, it is certain that it was not until Howe had independently invented his own machine and proved its utility to the public satisfaction, that Hunt thought his device of sufficient importance to cover it with a patent. His application was rejected "on the ground of abandonment", the courts holding that the patent law is framed for the protection and reward of such inventors as disclose their inventions for the public benefit. If Hunt's machine was practical, as he claimed, we have here a notable instance of the folly of allowing a useful invention to lie dormant until some independent inventor has achieved the same result and demonstrated its commercial value. Similar cases to this of Hunt and Howe are not far to seek. They all teach us that, if the first inventor believes his device to be practical and valuable, he should hasten to place himself beneath the protection of the patent law but that if he loses faith in its possibilities and value and gives up his search, he should be content to leave the field to others and "for ever hold his peace". Whatever credit may be due to the early machines above mentioned and to the later experiments of Hunt, the fact remains that Elias Howe did independently invent a practical sewing machine, which contained the three essential features of a needle with the eye at the point, a shuttle operating beneath the cloth to form the lock stitch and an automatic feed; that he had sufficient faith in his machine to cover it with a patent and that his unconquerable perseverance enabled him to convince the world of its commercial utility and establish its reputation as one of the most beneficial inventions of the age.

The inventor of the sewing machine, Elias Howe, was born in 1819 at Spencer, Massachusetts. His father was a farmer and miller, whose means were so small that Howe was put to work at bread winning when he was yet a mere child. At twenty we find him a machinist in the shop of a Mr. Davis, of Boston, Massachusetts , where he was first started on his investigation of the possibilities of mechanical sewing by hearing a capitalist remark to his employer that a large fortune awaited the man who could invent a sewing machine. At the outset he lost much valuable time in the endeavor to copy the motions of sewing by hand. If young Howe had known something of the early attempts of Saint, Thimonnier and others, he would have given his sewing machine to the world some years earlier than he did; but he had to go over the road that others had traversed before him, trying in vain to sew successfully with a needle pointed at both ends and having the eye at the center. It was in 1844 that he abandoned the attempt to imitate the hand stitch and conceived the idea of using two separate threads, on either side of the cloth and forming the stitch by the co-operation of a shuttle. He was on the right track at last and it was a natural step to shift the eye from the center to the point of the needle, so as to more readily form the loop for the passage of the shuttle. He did this and in October, 1844, by means of a rough model, he had satisfied himself that his device would sew. Howe was very poor and in spite of the priceless secret which lay hidden in his brain he found himself quite unable to purchase even the material to build a working machine. Fortunately for him and the world at large, he was able to induce a former schoolmate, George Fisher, to provide $500 for the expenses of constructing a machine and to board Howe and his family while it was being built, in consideration of which he was to acquire a half interest in the patent when it should be taken out. The work was finished by April, 1845 and in July he sewed two complete suits of clothes for himself and Fisher. Then came the heartache and disappointment. The tailors were suspicious of the machine and even after a public exhibition, in which the machine easily beat five of the swiftest sewers of a clothing manufactory, he received not a word of encouragement.

Howe went back to the garret of George Fisher's house and built another machine, for deposit in the Patent Office, this being his second machine and the one shown in our illustration. In all the annals of the Patent Office it would be difficult to find a "stronger" patent than this. So completely did it embody the essential features, that it carried its author safely through such a tempest of litigation as never fell upon a patentee before or since. Judged by comparison with later machines, the product of skilled and intelligent mechanics, this early effort of Howe's, with its piece of cloth stuck on the pins of a "baster plate", is a somewhat clumsy affair; but it sewed and it did so according to principles which will probably continue to govern the construction of sewing machines to the end of time.

By a study of the cut it will be seen that a curved, eye-pointed needle was carried at the end of a vertical vibrating lever and that it took its thread from a spool situated above the lever. The tension on the thread was secured by means of a spring brake, whose semicircular ends bore upon the spool, the pressure being regulated by a vertical thumb screw. The work was held in a vertical plane by means of pins projecting from the edge of a thin metal "baster plate", to which an intermittent motion was given by the teeth of a pinion. Above the "baster plate" was the shuttle race, through which the shuttle, carrying the second thread, was driven by means of two strikers, which were operated by two arms and cams located on the horizontal main shaft.

After securing his patent, Howe, discouraged by his reception in America, determined to introduce his machine in England and sent one over by his brother, Amasa B. Howe, to London, where a Cheapside manufacturer of corsets agreed to furnish money to promote the new venture. The following year, 1847, we fnd Howe in London trying, a part of the bargain, to adapt his machine to the sewing of corsets. Then followed two years of heartbreaking failure, in the course of which the inventor sank steadily into poverty. From three small rooms, he moves into one in the poorest part of Surrey. He borrows from a chance friend the means for bare existence and the money to send his sick wife to America. Then he finishes a machine worth $250, which he sells for $25 and finally he pawns his first machine and his patent for money to carry him back to America, where he arrives, practically penniless, in April, 1849.

From this time on the tide of fortune sets steadily in his favor. He discovers that in his absence his shuttle machine has been built and sold freely in America and that the mechanical world is waking up to its great possibilities. With the assistance of his father he commenced an infringement suit against those parties who were making his machine, or machines embodying his claims and after a bitter fight he came off completely victorious. A vigorous attempt was made by I. M. Singer & Company to break the Howe patent, on the ground that an earlier machine (as already mentioned) had been made by Walter Hunt; but while the parts of the Hunt machine of 1834, which were recovered and produced in court, showed that he was "upon the track of the invention", the evidence showed that he had finally given up in despair of any practical results.

In 1854, Judge Sprague, of Massachusetts, in giving a verdict for Howe, observed that " there is no evidence in this case that leaves a shadow of doubt that, for all the benefit conferred upon the public by the introduction of a sewing machine, the public are indebted to Mr. Howe."His success in the Singer suit was followed by a verdict against other infringers and they were obliged to pay royalties, (at first $25 on each machine), which in themselves ultimately gave him a princely income. He also established a factory in New York and, having bought up the remainder of his patent, he commenced to manufacture his own machine. His patent was extended for seven years, in 1860 but another application, in 1867, was denied. He was decorated with the cross of the Legion of Honor by France, in 1867 and died on October, 3th in the same year.

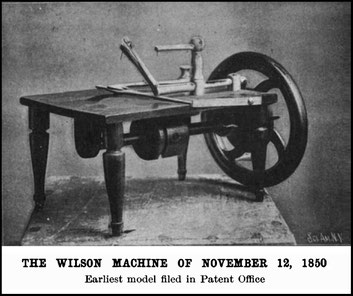

Next to Howe, the name of Allen B. Wilson claims notice as the inventor who has done the most to give us the present perfected sewing machine. To him we are indebted for those two most ingenious and beautiful pieces of mechanism: the rotating hook and the four-motion feed. He claims to have conceived the idea of a sewing machine in 1847. His first machine was built during the spring of 1849, while he was in the employ of a Mr. Barnes, of Pittsfield, Massachusetts, a cabinet maker. In the same year he built a second and better machine and "up to this time", says, "I had never seen or heard of a sewing machine other than my own". He sells a one-half interest in the invention to Joseph N. Chapin, of North Adams and with the proceeds takes out his first patent, which bears date November 12, 1850. The model of this machine, now in the Patent Office, is shown in the accompanying illustration. It formed a lock stitch by means of a curved needle on a vibrating arm above the cloth plate and a reciprocating two pointed shuttle traveling in a curved race below the plate. The feed motion was obtained by the two metal bars which are seen intersecting above the shuttle race. The lower bar, called the feed bar, had teeth on its upper face and by means of a transverse sliding motion it moved the cloth, which was placed between the two bars, the desired distance, as each stitch was made.

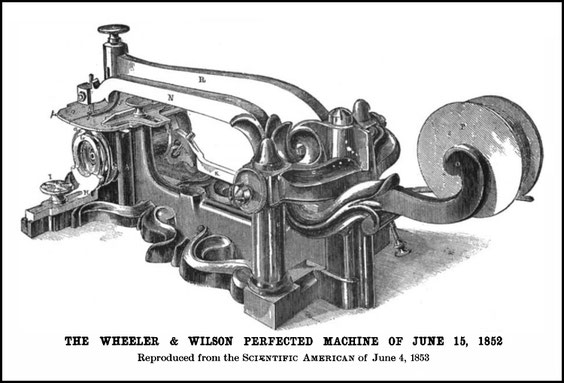

In 1851 Wilson patented his famous rotating hook, which performs the functions of a shuttle by seizing the upper thread and throwing its loop over a circular bobbin containing the under thread. This simplified the construction of the machine by getting rid of the reciprocating motion of the ordinary shuttle and contributed to make a light and silent running machine, eminently adapted to domestic use.

In 1852 Mr. Wilson patented his four-motion feed, which, in combination with a spring presser foot, may be said to form the basis of all modern feeding mechanisms. The feed bar, as its name indicates, had four distinct motions, two vertical and two horizontal. It was first raised by the action of an eccentric on the driving shaft, then carried forward by a cam formed on the side of the eccentric (by which operation the work was shifted the desired distance), then it dropped and finally it was drawn back by a spring to its original position. This machine, as shown in our engraving, uses the curved needle and embodies the rotating hook and the four-motion feed.

The latest type of this machine uses a vertical needle bar and a straight needle. Wilson had the good fortune soon after securing his patent to interest Nathaniel Wheeler, a young carriage maker who possessed some capital, in his machine and out of this connection grew the great house of Wheeler & Wilson. Unquestionably, the association of Mr. Wheeler with the sewing machine at the very inception of the industry was very largely answerable for its early and rapid success. It is rarely that the inventive and the commercial instinct are combined in the same man. It is certain they were not in Wilson. Wheeler, on the other hand, was eminently qualified by his wisdom, tact and engaging presence to promote the interests of the new device. He succeeded in interesting some of the wealthy capitalists of the day and the successful career of the Wheeler & Wilson establishment is a tribute to his undoubted business ability.

In 1851 W. O. Grover and W. E. Baker patented a machine which made the "Grover & Baker stitch". They used two needles, one above and the other below the material, the lower needle passing horizontally through the loop of the upper thread and producing a double chain stitch on the under side of the cloth. Great thing were hoped from the double chain stitch by its promoters and in the first twenty years its yearly sales rose to over 50.000; but, while it is specially adapted to certain classes of work, it has never won the popularity of the shuttle lock stitch.

To Mr. James E. A. Gibbs the world is indebted for the single thread rotating hook machine. Mr. James Parton, in his historical review of this industry, written in 1871, says: "Twelve years ago, Mr. James E. A. Gibbs, a Virginia farmer, saw in the Scientific American a picture of a sewing machine. The working of the apparatus was very plain down to the moment when the needle perforates the cloth and he fell into the habit of musing upon the course of events after the point of the needle was lost to view. The result of his cogitations, aided by infinite whittling, was the ingenious little revolving hook, which constitutes the peculiarity of the Willcox & Gibbs machine". The rotating hook, which is placed below the cloth plate, seizes the loop and during the ascent of the needle, it gives a twist to the thread and spreads it out beneath the needle hole ready for the next descent of the needle, when the hook catches another loop and repeats the operation.

Patent US 8.294, of August 12, 1851, introduced one of the most useful machines and one of the most remarkable men, that have figured in the development of the sewing machine. Isaac Merritt Singer, strolling player, theater manager, inventor and millionaire, brought into the business a new machine and novel methods of exploitation, which gave a powerful impulse to the youthful industry. The Singer improvements met the demand of the tailoring and leather industries for a heavier and more powerful machine. Our illustration shows the original machine upon which the patent of 1851 was granted. The novelties consisted in the circular feed wheel below the cloth plate, which had a serrated periphery projecting slightly above the plate and was fed by a rock shaft and pawl, a thread controller and the use of gear wheels and shafting to transmit the power from the hand wheel to the two countershafts for working the vertical needle and the shuttle. Singer was also the first to introduce foot power in place of the hand-driven crank wheel. He was a man of astonishing energy and fertility of resource and he was the originator of the system of sale by agents, which has done so much to introduce the sewing machine into the domestic circle.

Before passing on to a consideration of the statistics of the sewing machine, mention should be made of the application of this remarkable invention to the shoe and leather industries, where it has worked something like a revolution. The hand sewing of the uppers has given place to the quicker work of the machine and this in turn led to the invention of the justly celebrated McKay machine for sewing on the soles of shoes, which was first introduced in 1861. According to Mr. Frederick G. Bourne, president of the Singer Manufacturing Company, " it is stated that as many as 900 pairs of shoes have been sewed on one machine in one day of ten hours and that over 350.000.000 pairs of shoes have been made on the McKay machine up to the year 1877 in the United States and probably an equal or greater number in Europe". This machine used a waxed thread and made a chain stitch.

The Goodyear, a later machine, makes the lock stitch with a waxed thread and sews on the sole in the same way as it is done by hand. One could wish to dwell at length upon many of the remarkably ingenious applications of the sewing machine to the various trades and make mention of the glove stitcher, the buttonhole machine and many others, but we must pass on to general statistics.

In 1856 the owners of the original sewing machine patents formed the famous "sewing machine combination" for the establishment of a common license fee and for the protection of their mutual interests. The combination included Elias Howe, the Wheeler & Wilson Manufacturing Company, the Grover & Baker Sewing Machine Company and I. M. Singer & Company. Any manufacturer who had a machine with reasonable claims to novelty was admitted on payment of the license. The records of this combination furnish us with valuable statistics of the sewing machine industry up to the year 1876, when the patents expired; an extract from these records is given below:

The above reports show that, in the last years of the combination, the yearly sales of machines in the United States averaged 575.000! The subsequent census reports further indicate that the annual sales during the next fourteen years averaged over half a million and a canvass which we have recently made of the leading firms in the United States shows that the yearly output in 1896 may be put down at between 600.000 and 700.000. Furthermore, the records of the Bureau of Statistics show that the total value of the exports of sewing machines from 1865 to 1895 reaches the large sum of $67.000.000. Some conception of the patient investigation, intelligent thought and time and money that have been spent in perfecting the sewing machine may be had from the fact that from 1842 to 1895 over 7.000 patents had been granted on its various modifications! Such has been the history of the sewing machine and the whole field of invention it would be difficult to find a device which has ministered more intimately to the wants of the race than this. It has brought gold to the rich, good wage to the worker and best gift of all, sadly needed rest to weary fingers and aching eyes in many a cottage and garret.

As reproduction of historical newspaper articles and/or historical sources and/or historical artifacts, this works may contain errors of spelling and/or missing words and/or missing pages and/or poor pictures, etc.