- HOME

- Primary Sources

- The Invention of the Sewing Machine by Grace Rogers Cooper

- The Sewing Machine Combination or Sewing Machine Trust

- Vibrating Shuttle Sewing Machines History

- Running-Stitch Machines

- Button-Hole Machines

- Book-Sewing Machines

- Glove-Sewing Machines

- Shoe Making Machines

- Needles

- Shuttles & Bobbins

- Bobbin Winders

- Thread Tension Regulators

- Feed Reversing Mechanism

- Attachments and Accessories

- MANUFACTURERS AND DEALERS IN SEWING MACHINES

- BIOGRAPHICAL SKETCHES

- PATENTS

- DATING FRISTER & ROSSMANN

- FRISTER & ROSSMANN

- BRITISH Machines

- BRITISH Machines Part 1

- BRITISH Machines Part 2

- BRADBURY & Co.

- BRITANNIA SEWING MACHINE COMPANY

- BRITISH SEWING MACHINE COMPANY Ltd

- ECLIPSE MACHINE COMPANY

- ESSEX

- GRAIN E. L. Ltd

- W. J. HARRIS & C0.

- IMPERIAL SEWING MACHINE CO.

- JONES & CO.

- LANCASHIRE SEWING MACHINE Co

- SELLERS W.

- SHEPHERD, ROTHWELL & HOUGH

- VICKERS

- WEIR'S

- AMERICAN Machines

- AETNA SEWING MACHINE

- AMERICAN B.H.O. & SEWING MACHINE COMPANY

- AMERICAN SEWING MACHINE COMPANY

- AVERY SEWING MACHINE COMPANY

- BARTHOLF SEWING MACHINE COMPANY

- BARTLETT SEWING MACHINE COMPANY

- BARTRAM & FANTON Mfg. Co.

- BECKWITH SEWING MACHINE Co.

- BOYE NEEDLE COMPANY

- BURNET, BRODERICK & CO.

- CONTINENTAL MANUFACTURING Co.

- DAVIS SEWING MACHINE CO.

- DEMOREST SEWING MACHINE MANUFACTURING CO.

- DOMESTIC SEWING MACHINE COMPANY

- DORCAS Sewing Machine

- EMPIRE SEWING MACHINE COMPANY

- EPPLER & ADAMS SEWING MACHINE COMPANY

- GOODSPEED & WYMAN S.M. Co.

- GREIST MANUFACTURING COMPANY

- GROVER & BAKER SMC

- HEBERLING RUNNING STITCH GUAGING MACHINE Co.

- HIBBARD, SPENCER, BARTLETT & Co.

- HODGKINS MACHINE

- HOWE MACHINE COMPANY (Elias)

- HOWE S. M. C. (Amas)

- N. HUNT & CO.

- HUNT & WEBSTER

- JOHNSON, CLARK & CO.

- LEAVITT & CO.

- LEAVITT SEWING MACHINE COMPANY

- LEAVITT & BRANT

- LENOX MANUFACTURING COMPANY

- NETTLETON & RAYMOND SEWING MACHINES

- NEW HOME SEWING MACHINE COMPANY

- NICHOLS & BLISS

- NICHOLS & Co.

- NICHOLS, LEAVITT & CO.

- REMINGTON SEWING MACHINE COMPANY

- REECE BUTTON HOLE MACHINE COMPANY

- SINGER

- SMYTH MANUFACTURING COMPANY

- UNION BUTTONHOLE and EMBROIDERY MACHINE COMPANY

- UNION BUTTON-HOLE MACHINE COMPANY

- UNION BUTTON SEWING MACHINE COMPANY

- TABITHA Sewing Machine

- WARDWELL MANUFACTURING COMPANY

- WATSON, WOOSTER & Co.

- WEED SMC

- WHEELER & WILSON

- WHITE SEWING MACHINE COMPANY

- WILLCOX & GIBBS

- WILSON SEWING MACHINE COMPANY

- CANADIAN Machines

- GERMAN Machines

- Deutsche Nähmaschinen-Hersteller und Händler

- Development in industrial sales

- About innovations on sewing machines

- Bielefeld Nähmaschinenfabriken

- Nähmaschinen in Leipzig

- ADLER

- ANKER-WERKE A.G.

- BAER & REMPEL

- BEERMANN CARL

- BELLMANN E.

- BIESOLT & LOCKE

- BOECKE

- BREMER & BRÜCKMANN

- CLAES & FLENTJE

- DIETRICH & Co.

- DÜRKOPP

- GRIMME, NATALIS & Co.

- GRITZNER

- HAID & NEU

- HENGSTENBERG & Co.

- JUNKER & RUH

- KAISER

- LOEWE & Co. / LÖWE & Co.

- MANSFELD

- MÜLLER CLEMENS

- MUNDLOS

- OPEL

- PFAFF

- POLLACK , SCHMIDT & CO.

- SCHMIDT & HENGSTENBERG

- SEIDEL & NAUMANN

- SINGER NÄHMASCHINEN IN GERMANY

- STOEWER

- VESTA

- WERTHEIM

- WINSELMANN

- ITALIAN Machines

- HUNGARIAN / MAGYAR Machines / Varrógépek

- AUSTRIAN Machines

- BELGIAN Machines

- FRENCH Machines

- RUSSIAN Machines

- SWEDISH Machines

- SWISS Machines

- NATIONAL & INTERNATIONAL EXHIBITIONS

- 1850 NEW YORK - FAIR

- 1850 BOSTON

- 1851 LONDON

- 1851 NEW YORK - FAIR

- 1852 NEW YORK - FAIR

- 1853 NEW YORK - FAIR

- 1853 BOSTON

- 1853 DUBLIN

- 1853-4 NEW YORK

- 1854 MELBOURNE

- 1855 NEW YORK - FAIR

- 1855 PARIS

- 1856 BOSTON

- 1856 NEW YORK - FAIR

- 1860 STUTTGART

- 1861 MELBOURNE

- 1862 LONDON

- 1866 ALTONA

- 1869 BOSTON

- 1873 VIENNA World Exhibition

- 1876 PHILADELPHIA

- 1884 LONDON Health Exhibition

- 1884 LONDON International and Universal Exhibition

- 1885 LONDON South Kensington Exhibition

- 1887 LONDON American Exhibition

- 1889 PARIS Exposition Universelle

- 1893 LONDON The Sewing and Domestic Machines' Show

- CURIOSITIES

- READING ROOM

- SEWING MACHINE MUSEUMS - Links

- USEFUL LINKS

US PATENTS

FOR

SHUTTLES & BOBBINS

Abridgments of Specifications Relating to Shuttles & Bobbins

1846 - 2006

US PATENTS

*********************************************************

1846

*********************************************************

Eye-pointed needle in combination with shuttle for under thread, continuous thread from spools, lock-stitch, automatic feed the length of baster-plate.

curved needle & shuttle, lock-stitch sewing machine

September 10, 1846

*********************************************************

*********************************************************

1848

*********************************************************

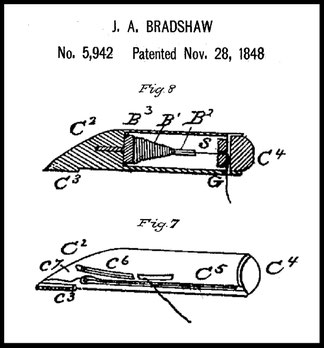

J. A. BRADSHAW

*********************************************************

1849

*********************************************************

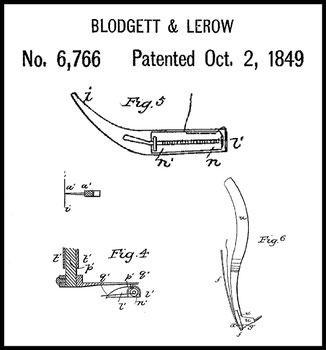

BLODGETT & LEROW

*********************************************************

1850

*********************************************************

ALLEN BENJAMIN WILSON

*********************************************************

1851

*********************************************************

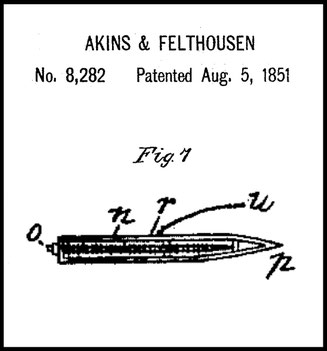

AKINS & FELTHOUSEN

*********************************************************

1851

*********************************************************

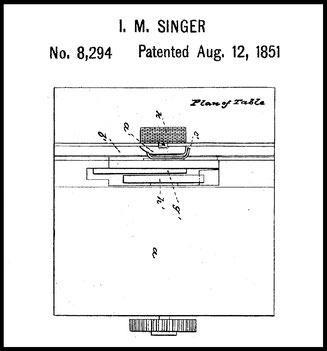

ISAAC MERRITT SINGER

*********************************************************

1851

*********************************************************

ALLEN BENJAMIN WILSON

*********************************************************

1852

*********************************************************

ALLEN BENJAMIN WILSON

Fig. 4 is a view in perspective of the rotating hook which opens the loops detached from the machine. Fig. 5 is a view in perspective of the bobbin which carries the thread which is to be passed through the loops. Fig. 6 is a view in perspective of the feed-bar and appendages detached from the machine.

This machine in certain points resembles that for which Letters Patent of the United States, bearing date the 12th day of August, 1851, were granted to me.

The main point of difference consists in the employment, in combination with the rotating hook for the purpose of carrying the thread which is to be passed through the loop formed in the needle thread, of a bobbin which is stationary in the line of its axis, the said bobbin being of such form and being so placed in relation to the said rotating hook as to cause the said rotating hook to extend the loop and pass it right over the bobbin.

*********************************************************

1852

*********************************************************

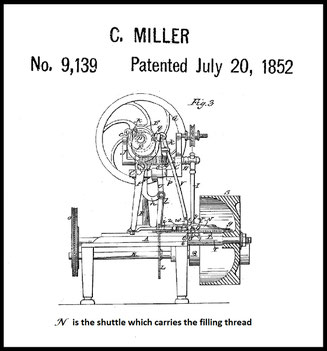

CHARLES MILLER

*********************************************************

1853

*********************************************************

THOMAS C. THOMPSON

Figure 1 represents a perspective view of the entire machine and Fig.2 represents the shuttle and shuttle-driver detached. The nature of my invention consists, first, in charging the race or shuttle with magnetism, for the purpose of keeping the shuttle in perfect contact with the face of the shuttle-race without the use of springs or holders of any kind, while at the same time I insure the taking up of every stitch.

*********************************************************

1863

*********************************************************

US 38.592 William A. Mack

May 19, 1863

*********************************************************

*********************************************************

1865

*********************************************************

US 49.091 Volney Cutter

August 1, 1865

*********************************************************

US 49.092 Volney Cutter

August 1, 1865

*********************************************************

VOLNEY CUTTER

*********************************************************

1876

*********************************************************

GEORGE W. BAKER

*********************************************************

1876

*********************************************************

US 177.042 Ausbert H. Wagner

Shuttle for Sewing Machine

The design of my invention is to reduce the weight and lessen the circumference of a shuttle and enable dust or dirt to escape from its interior when in use; to which end it consists in a sewing machine shuttle having its sides slotted longitudinally at two points, substantially as and for the purpose hereinafter specified.

The weight of the shuttle is materially reduced by the removal of so much of its walls and thereby the noise and jar of the machine is correspondingly lessened, while, by means of the lower opening, dust and dirt, which would otherwise accumulate within and interfere with the operation of the bobbin, are permitted to fall harmlessly outward. Having thus fully set forth the nature and merits of my invention, what I claim as new is:

The hereinbefore-described shuttle A, provided within its outer and lower sides with the longitudinal openings or slots a and a, substantially as and for the purpose specified.

May 2, 1876

*********************************************************

1878

*********************************************************

US 200.305 James F. Hutton

Tension Device for Shuttle

The object of my invention is to construct a simple and effective tension device for shuttle. I claim as my invention:

The combination of the shuttle-casing A, the bobbin B, adapted to bearings in the casing and having a head, b, the lever D, having a short arm adapted to bear upon the periphery of the head b and the screw e, for adjusting the lever, all substantially as specified. I claim as my invention:

The combination of the shuttle-casing A, the bobbin B, adapted to bearings in the casing and having a head b, the lever D, having a short arm adapted to bear upon the periphery of the head b and the screw e, for adjusting the lever, all substantially as specified.

February 12, 1878

*********************************************************

US 200.606 Philip Diehl

Shuttles for Sewing Machine

Assignor to The Singer Manufacturing Company

My invention consists of a solid frame shuttle, which exposes the bobbin to view and is without hinge or joint; also, of the combination of the said solid frame shuttle with devices for retaining the bobbin and for operating on the shuttle-thread, all as specified in the claims at the close of this description.

I claim as my invention:

1. A. solid frame shuttle for a sewing machine, consisting, substantially as before set forth, of the jointless bail and plate and means for detachably supporting the bobbin on the bail.

2. The combination, substantially as before set forth, of the jointless bail and plate frame shuttle with a spring-latch, to hold the bobbin to the bail.

3. The combination, substantially as before set forth, of the jointless bail and plate frame shuttle with the tension-spring to make tension on the shuttle-thread.

4. The combination, substantially as before set forth, of the jointless bail and plate frame shuttle, the tension-spring and the thread-guard.

February 26, 1878

*********************************************************

US 202.602 Nesbitt D. Stoops

Shuttle for Sewing Machine

The object of this invention is:

First, to produce a practically-round shuttle, or one having all of its friction-surfaces formed on curved lines and adapted to have its bobbin inserted from the top instead of through the end, as has been the case heretofore in this class of shuttles. Second, to provide such a shuttle with a reliable, simple and ready means for regulating the tension of its thread and, third, to facilitate the threading of the shuttle.

In accomplishing these purposes my invention consists, first, in providing the pivoted lid of the shuttle with a flat tension-spring located on its upper surface and a combined shuttle-tension spring and latch connected therewith on its lower surface and adapted to be moved by an adjusting-screw extending through the shell of the shuttle, whereby the shuttle-lid may be held in place and the tension adjusted by the same screw; second, in a sewing machine shuttle having a pivoted or hinged top or lid, forming a part of the bobbin case and provided with tapering extension projecting beyond the heel of the shuttle, for the purpose of supporting a slack-thread guard-spring, which also extends beyond the heel of said shuttle, whereby the shuttle-thread is carried back beyond the heel of the shuttle and held down upon the lid during its for ward movement and the needle-loop extended while being drawn up until nearly within the fabric and thus prevented from twisting, while, during the backward throw, its thread is carried out of the path of the needle and bad stitches resulting from the knotting of the needle and shuttle-threads thereby prevented. I claim:

1. The combination, with a shuttle-shell, substantially as herein described, of a pivoted lid having a flat spring arranged upon and attached by one end to its upper surface and a tension-spring and latch connected with said spring and attached to the lower surface of the said lid and adapted to be moved by an adjusting-screw extending through the shell of the shuttle, substantially as and for the purpose set forth.

2. The combination, with a sewing machine shuttle, of a pivoted or hinged lid, forming a part of the bobbin-case and provided with a tapering extension projecting beyond the heel of the shuttle and a slack-thread guard spring, also extending beyond the shuttle-heel and along a portion of the lid, substantially as and for the purpose set forth.

April 16, 1878

*********************************************************

US 207.004 Eloi Bouscay

Shuttle for Sewing Machine

My invention relates to improvements in sewing machine shuttles; more especially in that class of the same which does not require the thread to be passed endwise through an eye formed in the shuttle, but which provides an open end slot extending forward from the heel of the shuttle, so as to permit the thread to be passed laterally into said slot and from thence carried forward to be connected with the tension spring. Hitherto, the tension springs used with this class of shuttles have been of such character as required them to be removed, raised or otherwise displaced from their operative position upon the shuttle, in order to engage the thread therewith.

I claim as new and desire to secure by Letters Patent, is:

1. The combination, with a shuttle, of a tension-spring formed with the angular-arm projection, adapted to permit the thread to be passed beneath the same without displacement of the main body of the spring, substantially as set forth.

2. The combination, with a shuttle formed with the transverse recess in its outer side body, of a tension-spring provided with the angular. arm projection fitting into said recess and which is adapted to have the thread passed under the same and thereby secured in proper tension without passage endwise through an eye thereof or by being passed beneath the main body of the spring, substantially as set forth.

3. The combination, with a shuttle formed with the diagonal open-end slot and the connecting longitudinal slot, of the tension-spring, which is made with the open-slotted eye and the angular-arm projection, beneath which latter the thread is passed, the same being adapted to have the thread held in proper tension without passage endwise through eyes formed either in the shuttle or spring and without being passed beneath the main body of the spring, substantially as set forth.

4. The combination, with a shuttle provided both with a notch in its heel and with the slot which leads therefrom, of a lid, whose free end is held in said notch by the spring-pressure of the slotted shuttle, said lid being hinged directly to the body of the shuttle, which latter is formed of increased thickness at this point, substantially as set forth.

August 13, 1878

*********************************************************

*********************************************************

2006

*********************************************************

DANIELE CERLIANI

US Patent for Central Bobbin Shuttle

(US 7.069.868 July 4, 2006)

Inventor: Daniele Cerliani, Piazza Dante 4 - 27100, Pavia (Italy)

A shuttle unit of the type comprising a discoid shuttle body provided with two conical portions, one front and one rear, disposed specularly with respect to the median plane of said shuttle body passing through the race of the shuttle body, and a shuttle driver guided in rotation to make the shuttle body oscillate. The front and rear portions define a containing cavity for the bobbin case and the thread bobbin. The front conical portion forms a base angle with the median plane of the shuttle body comprised between 43° and 49°.

*********************************************************